Page 51 - Mechatronics with Experiments

P. 51

Printer: Yet to Come

October 9, 2014 7:39 254mm×178mm

JWST499-c01

JWST499-Cetinkunt

INTRODUCTION 37

For redundancy purposes, all hydraulic actuators (electro-hydraulic servo actuators

(EHSA) and motors) are powered by one of three independent hydraulic power supply

systems. A typical hydraulic power supply system is of constant pressure type in aerospace

applications. The constant pressure may be supplied by a fixed displacement pump with a

pressure limiting unload-valve or a output pressure regulated variable displacement pump.

The second option is more energy efficient in converting mechanical engine power to

desired hydraulic power.

These hydraulic power supply systems are named Blue, Green, and Yellow. In order

to meet reliability requirements for the supply systems, several independent power sources

are used. The main power sources for aircrafts are the engines. They not only create the

necessary thrust for flight, but also supply power to drive generators (integrated drive gen-

erator, IDG) and hydraulic pumps (engine driven pump (EDP)). An additional electrically

driven pump is connected to the yellow system. A backup for the blue system is the ram air

turbine (RAT), which is activated (roughly located below the cockpit) in case both engines

fail. The green and the yellow hydraulic systems are connected by a so-called power transfer

unit (PTU), comprising of two hydraulic machines (one fixed, one variable displacement),

both of which can operate as hydraulic pumps or motors. Thus, energy can be transferred

between both supply systems. The PTU might be used during normal operation in case

the power demand from one of the two hydraulic systems is too high (e.g., during deploy-

ment of slats and flaps). The “hydraulic power consumers” (actuators) are connected to the

hydraulic supply systems with different priorities controlled by a priority valve, with the

primary flight control actuators at highest priority (Figure 1.27).

Every actuator in flight control surfaces uses one of the constant supply pressure

lines as a hydraulic power source, and meters (controls) the flow to the rotary hydraulic

Control surface

Wing

rear spar

Mode selector valve

Servo valve

Hydraulic Hydraulic

system 1 system 2

(e.g. blue) (e.g. yellow)

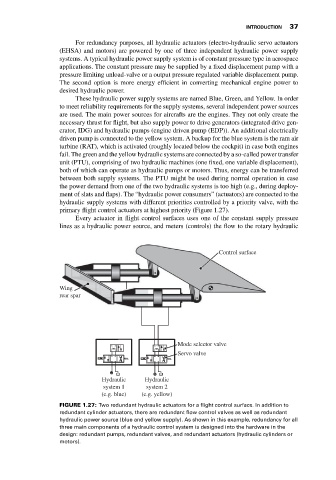

FIGURE 1.27: Two redundant hydraulic actuators for a flight control surface. In addition to

redundant cylinder actuators, there are redundant flow control valves as well as redundant

hydraulic power source (blue and yellow supply). As shown in this example, redundancy for all

three main components of a hydraulic control system is designed into the hardware in the

design: redundant pumps, redundant valves, and redundant actuators (hydraulic cylinders or

motors).