Page 735 - Mechatronics with Experiments

P. 735

PROGRAMMABLE MOTION CONTROL SYSTEMS 721

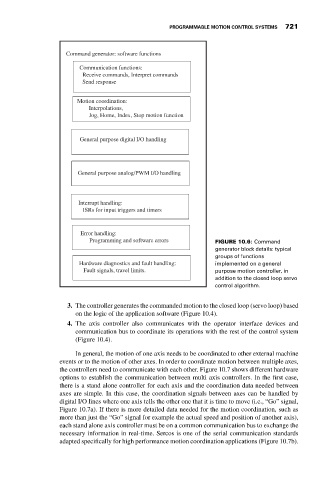

Command generator: software functions

Communication functions:

Receive commands, Interpret commands

Send response

Motion coordination:

Interpolations,

Jog, Home, Index, Stop motion function

General purpose digital I/O handling

General purpose analog/PWM I/O handling

Interrupt handling:

ISRs for input triggers and timers

Error handling:

Programming and software errors FIGURE 10.6: Command

generator block details: typical

groups of functions

Hardware diagnostics and fault handling: implemented on a general

Fault signals, travel limits. purpose motion controller, in

addition to the closed loop servo

control algorithm.

3. The controller generates the commanded motion to the closed loop (servo loop) based

on the logic of the application software (Figure 10.4).

4. The axis controller also communicates with the operator interface devices and

communication bus to coordinate its operations with the rest of the control system

(Figure 10.4).

In general, the motion of one axis needs to be coordinated to other external machine

events or to the motion of other axes. In order to coordinate motion between multiple axes,

the controllers need to communicate with each other. Figure 10.7 shows different hardware

options to establish the communication between multi axis controllers. In the first case,

there is a stand alone controller for each axis and the coordination data needed between

axes are simple. In this case, the coordination signals between axes can be handled by

digital I/O lines where one axis tells the other one that it is time to move (i.e., “Go” signal,

Figure 10.7a). If there is more detailed data needed for the motion coordination, such as

more than just the “Go” signal for example the actual speed and position of another axis),

each stand alone axis controller must be on a common communication bus to exchange the

necessary information in real-time. Sercos is one of the serial communication standards

adapted specifically for high performance motion coordination applications (Figure 10.7b).