Page 43 - Zero is Possible - Volume 2

P. 43

Milaki Cement Plant

Environment

Green today,

greener tomorrow! GREECE Cement

Opportunity this process repeated

The fugitive dust approximately every two

produced by the non- months to sustain crust

covered solid fuel yard stability.

at the Milaki plant has

consistently been a Results

significant concern. The production of fugitive

It impacts the health dust has been minimized

of our employees and by covering the piles with

contractors, compromises a stable crust. Once dried,

the overall housekeeping this crust prevents wind Dimitrios Chanis

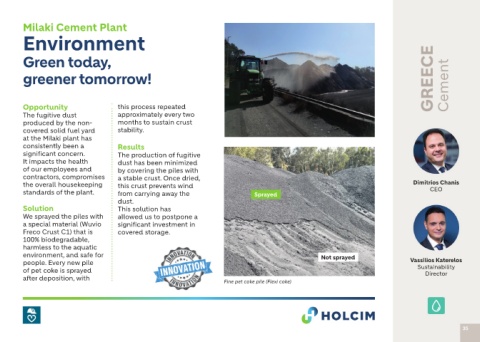

standards of the plant. from carrying away the Sprayed CEO

dust.

Solution This solution has

We sprayed the piles with allowed us to postpone a

a special material (Wuvio significant investment in

Freco Crust C1) that is covered storage.

100% biodegradable,

harmless to the aquatic

environment, and safe for Not sprayed

people. Every new pile Vassilios Katerelos

Sustainability

of pet coke is sprayed Director

after deposition, with

Fine pet coke pile (Flexi coke)

35