Page 207 - Icon Ridge Hardware & Fixing Technology Catalog

P. 207

Fixing technology

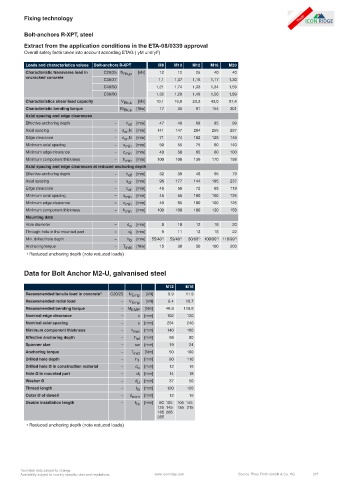

Bolt-anchors R-XPT, steel

Extract from the application conditions in the ETA-08/0339 approval

Overall safety factir taken into account according ETAG ( γM und γF)

Loads and characteristics values Bolt-anchors R-XPT M8 M10 M12 M16 M20

Characteristic transverse load in C20/25 N [kN] 12 12 25 40 40

Rk,p

uncracked concrete

C30/37 1,1 1,37 1,16 1,17 1,30

C40/50 1,21 1,74 1,33 1,34 1,59

C50/60 1,32 1,20 1,49 1,50 1,89

Characteristics shear load capacity V Rk,s [kN] 10,1 16,0 23,3 43,0 67,4

Characteristic bending torque M Rk,s [Nm] 17 35 61 154 301

Axial spacing and edge clearances

Effective anchoring depth – h [mm] 47 49 68 85 99

ef

Axial spacing – s ,N [mm] 141 147 204 255 297

cr

Edge clearance – c ,N [mm] 71 74 102 128 149

cr

Minimum axial spacing – s [mm] 50 55 75 90 140

min

Minimum edge clearance – c min [mm] 40 50 65 80 100

Minimum component thickness – h min [mm] 100 100 136 170 198

Axial spacing and edge clearances at reduced anchoring depth

Effective anchoring depth – h ef [mm] 32 39 48 65 79

Axial spacing – s cr [mm] 96 177 144 195 237

Edge clearance – c cr [mm] 48 59 72 98 119

Minimum axial spacing – s [mm] 45 55 100 100 125

min

Minimum edge clearance – c min [mm] 40 65 100 100 125

Minimum component thickness – h min [mm] 100 100 100 130 158

Mounting data

Hole diameter – d o [mm] 8 10 12 16 20

Through-hole in the mounted part – d f [mm] 9 11 13 18 22

Min. drilled hole depth – h 0 [mm] 55/40 1) 59/49 1) 80/60 1) 100/80 1) 119/99 1)

Anchoring torque – T [Nm] 15 30 50 100 200

inst

1) Reduced anchoring depth (note reduced loads)

Data for Bolt Anchor M2-U, galvanised steel

M12 M16

Recommended tensile load in concrete 1) C20/25 N Emp [kN] 9.9 11.9

Recommended radial load – V Emp [kN] 8.4 15.7

Recommended bending torque – M [Nm] 46.8 118.6

EMP

Nominal edge clearance – c [mm] 102 120

Nominal axial spacing – s [mm] 204 240

Minimum component thickness – h [mm] 140 160

min

Effective anchoring depth – h ef [mm] 68 80

Spanner size – sw [mm] 19 24

Anchoring torque – T inst [Nm] 50 100

Drilled hole depth – h [mm] 90 110

1

Drilled hole Ø in construction material – d o [mm] 12 16

Hole Ø in mounted part – d f [mm] 14 18

Washer Ø – d [mm] 37 50

µ

Thread length – l G [mm] 120 120

Outer Ø of dowell – d nom [mm] 12 16

Usable installation length – t fix [mm] 90 105 105 145

125 145 185 215

165 205

265

1) Reduced anchoring depth (note reduced loads)

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 207