Page 211 - Icon Ridge Hardware & Fixing Technology Catalog

P. 211

Fixing technology

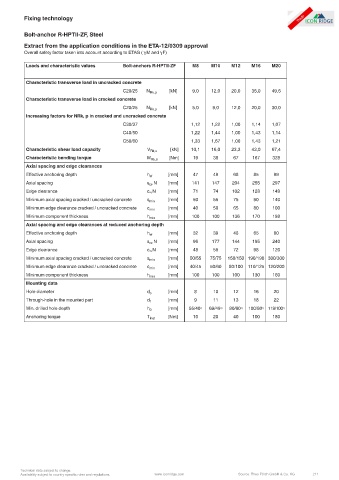

Bolt-anchor R-HPTII-ZF, Steel

Extract from the application conditions in the ETA-12/0309 approval

Overall safety factor taken into account according to ETAG ( γM and γF)

Loads and characteristic values Bolt-anchors R-HPTII-ZF M8 M10 M12 M16 M20

Characteristic transverse load in uncracked concrete

[kN] 9,0 12,0 20,0 35,0 49,6

C20/25 N Rk,p

Characteristic transverse load in cracked concrete

[kN] 5,0 9,0 12,0 20,0 30,0

C20/25 N Rk,p

Increasing factors for NRk, p in cracked and uncracked concrete

C30/37 1,12 1,22 1,00 1,14 1,07

C40/50 1,22 1,44 1,00 1,43 1,14

C50/60 1,33 1,67 1,00 1,43 1,21

Characteristic shear load capacity V Rk,s [kN] 10,1 16,0 23,3 43,0 67,4

Characteristic bending torque M Rk,s [Nm] 19 38 67 167 328

Axial spacing and edge clearances

Effective anchoring depth h ef [mm] 47 49 68 85 99

Axial spacing s cr ,N [mm] 141 147 204 255 297

Edge clearance ccr,N [mm] 71 74 102 128 149

Minimum axial spacing cracked / uncracked concrete s min [mm] 50 55 75 90 140

Minimum edge clearance cracked / uncracked concrete c min [mm] 40 50 65 80 100

Minimum component thickness h min [mm] 100 100 136 170 198

Axial spacing and edge clearances at reduced anchoring depth

Effective anchoring depth h ef [mm] 32 39 48 65 80

Axial spacing s cr ,N [mm] 96 177 144 195 240

Edge clearance ccr,N [mm] 48 59 72 98 120

Minimum axial spacing cracked / uncracked concrete s min [mm] 50/55 75/75 150/150 190/190 300/300

Minimum edge clearance cracked / uncracked concrete c min [mm] 40/45 50/60 80/100 110/125 120/200

Minimum component thickness h min [mm] 100 100 100 130 160

Mounting data

Hole diameter d o [mm] 8 10 12 16 20

Through-hole in the mounted part d f [mm] 9 11 13 18 22

Min. drilled hole depth h 0 [mm] 55/40 1) 69/49 1) 80/60 1) 100/80 1) 119/100 1)

Anchoring torque T inst [Nm] 10 20 40 100 180

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 211