Page 486 - Icon Ridge Maintenance & Service Catalog

P. 486

Cutting, Sanding, Sawing, Surface Treatment

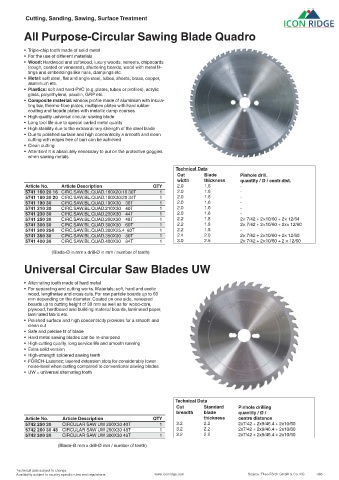

All Purpose-Circular Sawing Blade Quadro

• Triple-chip tooth made of solid metal

• For the use of different materials

• Wood: Hardwood and softwood, luxury woods, veneers, chipboards

(rough, coated or veneered), shuttering boards, wood with metal fit-

tings and embeddings like nails, clampings etc.

• Metal: soft steel, flat and angle steel, tubes, sheets, brass, copper,

aluminium etc.

• Plastics: soft and hard-PVC (e.g. plates, tubes or profiles), acrylic

glass, polyethylene, paxolin, GRP etc.

• Composite material: window profile made of aluminium with insula-

ting bar, thermo-fibre plates, multiplex plates with hard rubber

coating and facade plates with metallic damp courses

• High-quality universal circular sawing blade

• Long tool life due to special carbid metal quality

• High stability due to the extraordinary strength of the steel blade

• Due to polished surface and high concentricity a smooth and clean

cutting with edges free of burr can be achieved

• Clean cutting

• Attention! It is absolutely necessary to put on the protective goggles

when sawing metals.

Technical Data

Cut Blade Pinhole drill.

width thickness quantity / Ø / centr.dist.

Article No. Article Description QTY 2.0 1.6 -

5741 160 20 16 CIRC.SAW.BL.QUAD.160X20/16 30T 1 2.0 1.6 -

5741 180 30 20 CIRC.SAW.BL.QUAD.180X30/20 34T 1 2.0 1.6 -

5741 190 30 CIRC.SAW.BL.QUAD.190X30 38T 1 2.0 1.6 -

5741 210 30 CIRC.SAW.BL.QUAD.210X30 40T 1 2.0 1.6 -

5741 230 30 CIRC.SAW.BL.QUAD.230X30 44T 1 2.0 1.6 -

5741 250 30 CIRC.SAW.BL.QUAD.250X30 48T 1 2.2 1.8 2× 7/42 + 2×10/60 + 2× 12/64

5741 300 30 CIRC.SAW.BL.QUAD.300X30 60T 1 2.2 1.8 2× 7/42 + 2×10/60 + 2x× 12/60

5741 300 254 CIRC.SAW.BL.QUAD.300X25.4 60T 1 2.2 1.8 -

5741 350 30 CIRC.SAW.BL.QUAD.350X30 80T 1 2.4 2.0 2× 7/42 + 2×10/60 + 2× 12/60

5741 400 30 CIRC.SAW.BL.QUAD.400X30 84T 1 3.0 2.5 2× 7/42 + 2×10/60 + 2 × 12/60

(Blade-Ø in mm x drill-Ø in mm / number of teeth)

Universal Circular Saw Blades UW

• Alternating tooth made of hard metal

• For separating and cutting works. Materials: soft, hard and exotic

wood, lengthwise and cross cuts. For raw particle boards up to 60

mm depending on the diameter. Coated on one side, veneered

boards up to cutting height of 30 mm as well as for wood-core,

plywood, hardboard and building material boards, laminated paper,

laminated fabric etc.

• Polished surface and high concentricity provides for a smooth and

clean cut

• Safe and precise fit of blade

• Hard metal sawing blades can be re-sharpend

• High cutting quality, long service life and smooth running

• Extra solid version

• High-strength soldered sawing teeth

• FÖRCH-Lasertec; lasered extension slots for considerably lower

noise-level when cutting compared to conventional sawing blades

• UW = universal alternating tooth

Technical Data

Cut Standard Pinhole drilling

breadth blade quantity / Ø /

Article No. Article Description QTY thickness centre distance

5742 250 30 CIRCULAR SAW UW 250X30 40T 1 3.2 2.2 2x7/42 + 2x9/46.4 + 2x10/60

5742 260 30 48 CIRCULAR SAW UW 260X30 48T 1 3.2 2.2 2x7/42 + 2x9/46.4 + 2x10/60

5742 300 30 CIRCULAR SAW UW 300X30 48T 1 3.2 2.2 2x7/42 + 2x9/46.4 + 2x10/60

(Blade-Ø mm x drill-Ø mm / number of teeth)

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 486