Page 489 - Icon Ridge Maintenance & Service Catalog

P. 489

Cutting, Sanding, Sawing, Surface Treatment

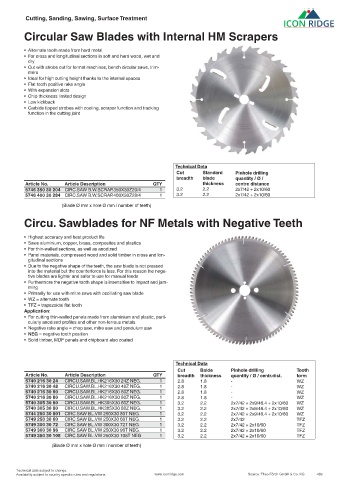

Circular Saw Blades with Internal HM Scrapers

• Alternate tooth made from hard metal

• For cross and longitudinal sections in soft and hard wood, wet and

dry

• Cut with strobe cut for format machines, bench circular saws, trim-

mers

• Ideal for high cutting height thanks to the internal spaces

• Flat tooth positive rake angle

• With expansion slots

• Chip thickness limited design

• Low kickback

• Carbide tipped strobes with cooling, scraper function and tracking

function in the cutting joint

Technical Data

Cut Standard Pinhole drilling

breadth blade quantity / Ø /

Article No. Article Description QTY thickness centre distance

5746 350 30 204 CIRC.SAW B.W.SCRAP.350X30Z20/4 1 3.2 2.2 2x7/42 + 2x10/60

5746 400 30 284 CIRC.SAW B.W.SCRAP.400X30Z28/4 1 3.2 2.2 2x7/42 + 2x10/60

(Blade Ø mm x hole Ø mm / number of teeth)

Circu. Sawblades for NF Metals with Negative Teeth

• Highest accuracy and best product life

• Saws aluminium, copper, brass, composites and plastics

• For thin-walled sections, as well as anodized

• Panel materials, compressed wood and solid timber in cross and lon-

gitudinal sections

• Due to the negative shape of the teeth, the saw blade is not pressed

into the material but the counterforce is less. For this reason the nega-

tive blades are lighter and safer to use for manual feeds

• Furthermore the negative tooth shape is insensitive to impact and jam-

ming

• Primarily for use with mitre saws with oscillating saw blade

• WZ = alternate tooth

• TFZ = trapezoidal flat tooth

Application:

• For cutting thin-walled panels made from aluminium and plastic, parti-

cularly anodised profiles and other non-ferrous metals

• Negative rake angle = chop saw, mitre saw and pendulum saw

• NEG = negative tooth position

• Solid timber, MDF panels and chipboard also coated

Technical Data

Cut Balde Pinhole drilling Tooth

Article No. Article Description QTY breadth thickness quantity / Ø / centr.dist. form

5740 216 30 24 CIRCU.SAW.BL.HK216X30 24Z NEG. 1 2.8 1.8 - WZ

5740 216 30 48 CIRCU.SAW.BL.HK216X30 48Z NEG. 1 2.8 1.8 - WZ

5740 216 30 60 CIRCU.SAW.BL.HK216X30 60Z NEG. 1 2.8 1.8 - WZ

5740 216 30 80 CIRCU.SAW.BL.HK216X30 80Z NEG. 1 2.8 1.8 - WZ

5740 305 30 60 CIRCU.SAW.BL.HK305X30 60Z NEG. 1 3.2 2.2 2x7/42 + 2x9/46.4 + 2x10/60 WZ

5740 305 30 80 CIRCU.SAW.BL.HK305X30 80Z NEG. 1 3.2 2.2 2x7/42 + 2x9/46.4 + 2x10/60 WZ

5744 250 30 801 CIRC.SAW BL.VW 250X30 80T NEG. 1 3.2 2.2 2x7/42 + 2x9/46.4 + 2x10/60 WZ

5749 250 30 60 CIRC.SAW BL.VW 250X30 60T NEG. 1 3.2 2.2 2x7/42 TFZ

5749 300 30 72 CIRC.SAW BL.VW 300X30 72T NEG. 1 3.2 2.2 2x7/42 + 2x10/60 TFZ

5749 300 30 96 CIRC.SAW BL.VW 250X30 96T NEG. 1 3.2 2.2 2x7/42 + 2x10/60 TFZ

5749 350 30 108 CIRC.SAW BL.VW 250X30 108T NEG 1 3.2 2.2 2x7/42 + 2x10/60 TFZ

(Blade Ø mm x hole Ø mm / number of teeth)

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 489