Page 493 - Icon Ridge Maintenance & Service Catalog

P. 493

Cutting, Sanding, Sawing, Surface Treatment

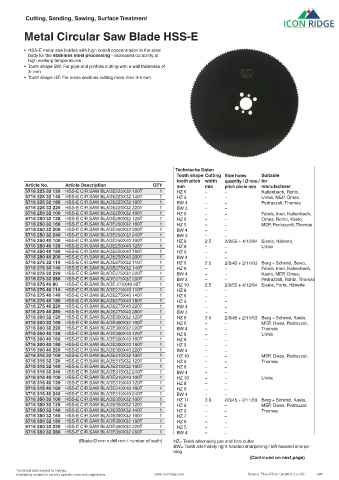

Metal Circular Saw Blade HSS-E

• HSS-E metal saw blades with high cobalt concentration in the steel

body for the stainless steel processing – increased durability at

high working temperatures

• Tooth shape BW: For pipe and profiles cutting with a wall thickness of

3- mm

• Tooth shape HZ: For cross sections cutting more than 4-5 mm

Technische Daten

Tooth shape Cutting Side holes Suitable

tooth pitch width quantity / Ø mm / for

Article No. Article Description QTY mm mm pitch circle mm manufacturer

5716 225 32 120 HSS-E CIR.SAW BLADE225X32 120T 1 HZ 6 – – Kaltenbach, Rohbi,

5716 225 32 140 HSS-E CIR.SAW BLADE225X32 140T 1 HZ 5 – – Ulmia, MEP, Omes,

5716 225 32 180 HSS-E CIR.SAW BLADE225X32 180T 1 BW 4 – – Pedrazzoli, Thomas

5716 225 32 220 HSS-E CIR.SAW BLADE225X32 220T 1 BW 3 – –

5716 250 32 100 HSS-E CIR.SAW BLADE250X32 100T 1 HZ 8 – – Fabris, Imet, Kaltenbach,

5716 250 32 128 HSS-E CIR.SAW BLADE250X32 128T 1 HZ 6 – – Omes, Rohbi, Kasto,

5716 250 32 160 HSS-E CIR.SAW BLADE250X32 160T 1 HZ 5 – – MEP, Pedrazzoli, Thomas

5716 250 32 200 HSS-E CIR.SAW BLADE250X32 200T 1 BW 4 – –

5716 250 32 240 HSS-E CIR.SAW BLADE250X32 240T 1 BW 3 – –

5716 250 40 100 HSS-E CIR.SAW BLADE250X40 100T 1 HZ 8 2.5 2/8/55 + 4/12/64 Eisele, Häberle,

5716 250 40 128 HSS-E CIR.SAW BLADE250X40 128T 1 HZ 6 – – Ulmia

5716 250 40 160 HSS-E CIR.SAW BLADE250X40 160T 1 HZ 5 – –

5716 250 40 200 HSS-E CIR.SAW BLADE250X40 200T 1 BW 4 – –

5716 275 32 110 HSS-E CIR.SAW BLADE275X32 110T 1 HZ 8 2.5 2/8/45 + 2/11/63 Berg + Schmid, Bewo,

5716 275 32 140 HSS-E CIR.SAW BLADE275X32 140T 1 HZ 6 – – Fabris, Imet, Kaltenbach,

5716 275 32 220 HSS-E CIR.SAW BLADE275X32 220T 1 BW 4 – – Kasto, MEP, Omes,

5716 275 32 280 HSS-E CIR.SAW BLADE275X32 280T 1 BW 3 – – Pedrazzoli, Rohbi, Thomas

5716 275 40 90 HSS-E CIR.SAW BLADE 275X40 90T 1 HZ 10 2.5 2/8/55 + 4/12/64 Eisele, Forte, Häberle

5716 275 40 110 HSS-E CIR.SAW BLADE275X40 110T 1 HZ 8 – –

5716 275 40 140 HSS-E CIR.SAW BLADE275X40 140T 1 HZ 6 – –

5716 275 40 180 HSS-E CIR.SAW BLADE275X40 180T 1 HZ 5 – –

5716 275 40 220 HSS-E CIR.SAW BLADE275X40 220T 1 BW 4 – –

5716 275 40 280 HSS-E CIR.SAW BLADE275X40 280T 1 BW 3 – –

5716 300 32 120 HSS-E CIR.SAW BLADE300X32 120T 1 HZ 8 2.5 2/8/45 + 2/11/63 Berg + Schmid, Kasto,

5716 300 32 160 HSS-E CIR.SAW BLADE300X32 160T 1 HZ 6 – – MEP, Owes, Pedrazzoli,

5716 300 32 220 HSS-E CIR.SAW BLADE300X32 220T 1 BW 4 – – Thomas

5716 300 40 120 HSS-E CIR.SAW BLADE300X40 120T 1 HZ 8 – – Ulmia

5716 300 40 160 HSS-E CIR.SAW BLADE300X40 160T 1 HZ 6 – –

5716 300 40 180 HSS-E CIR.SAW BLADE300X40 180T 1 HZ 5 – –

5716 300 40 220 HSS-E CIR.SAW BLADE300X40 220T 1 BW 4 – –

5716 315 32 100 HSS-E CIR.SAW BLADE315X32 100T 1 HZ 10 – – MEP, Owes, Pedrazzoli,

5716 315 32 120 HSS-E CIR.SAW BLADE315X32 120T 1 HZ 8 – – Thomas

5716 315 32 160 HSS-E CIR.SAW BLADE315X32 160T 1 HZ 6 – –

5716 315 32 240 HSS-E CIR.SAW BLADE315X32 240T 1 BW 4 – –

5716 315 40 100 HSS-E CIR.SAW BLADE315X40 100T 1 HZ 10 – – Ulmia

5716 315 40 120 HSS-E CIR.SAW BLADE315X40 120T 1 HZ 8 – –

5716 315 40 160 HSS-E CIR.SAW BLADE315X40 160T 1 HZ 6 – –

5716 315 40 240 HSS-E CIR.SAW BLADE315X40 240T 1 BW 4 – –

5716 350 32 100 HSS-E CIR.SAW BLADE350X32 100T 1 HZ 11 3.0 2/8/45 + 2/11/63 Berg + Schmid, Kasto,

5716 350 32 120 HSS-E CIR.SAW BLADE350X32 120T 1 HZ 9 – – MEP, Owes, Pedrazzoli

5716 350 32 140 HSS-E CIR.SAW BLADE350X32 140T 1 HZ 8 – – Thomas

5716 350 32 160 HSS-E CIR.SAW BLADE350X32 160T 1 HZ 7 – –

5716 350 32 180 HSS-E CIR.SAW BLADE350X32 180T 1 HZ 6 – –

5716 350 32 220 HSS-E CIR.SAW BLADE350X32 220T 1 HZ 5 – –

5716 350 32 280 HSS-E CIR.SAW BLADE350X32 280T 1 BW 4 – –

(Blade-Ø mm x drill mm / number of teeth) HZ= Teeth alternately pre and final cutter

BW= Teeth alternately right-handed sharpening / left-handed sharpe-

ning

(Continued on next page)

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 493