Page 488 - Icon Ridge Maintenance & Service Catalog

P. 488

Cutting, Sanding, Sawing, Surface Treatment

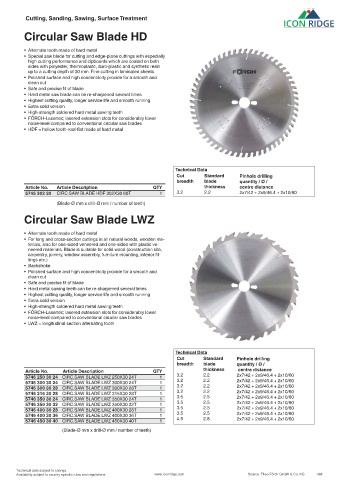

Circular Saw Blade HD

• Alternate tooth made of hard metal

• Special saw blade for cutting and edge-plane cuttings with especially

high cutting performance and cipboards which are coated on both

sides with polyester, thermoplastc, duro-plastic and synthetic resin

up to a cutting depth of 30 mm. Fine cutting in laminated sheets.

• Polished surface and high concentricity provide for a smooth and

clean cut

• Safe and precise fit of blade

• Hard metal saw blade can be re-sharpened several times

• Highest cutting quality, longer service life and smooth running

• Extra solid version

• High-strength soldered hard metal sawing teeth

• FÖRCH-Lasertec; lasered extension slots for considerably lower

noise-level compared to conventional circular saw blades

• HDF = hollow tooth-roof-flat made of hard metal

Technical Data

Cut Standard Pinhole drilling

breadth blade quantity / Ø /

Article No. Article Description QTY thickness centre distance

5745 302 30 CIRC.SAW BLADE HDF 302X30 60T 1 3.2 2.2 2x7/42 + 2x9/46.4 + 2x10/60

(Blade-Ø mm x drill-Ø mm / number of teeth)

Circular Saw Blade LWZ

• Alternate tooth made of hard metal

• For long and cross-section cuttings in all natural woods, wooden ma-

terials, also for one-sided veneered and one-sided with plastic ve-

neered materials. Blade is suitable for solid wood (construction site,

carpentry, joinery, window assembly, furniture mounting, interior fit-

tings etc.)

• Backstroke

• Polished surface and high concentricity provide for a smooth and

clean cut

• Safe and precise fit of blade

• Hard metal sawing teeth can be re-sharpened several times

• Highest cutting quality, longer service life and smooth running

• Extra solid version

• High-strength soldered hard metal sawing teeth

• FÖRCH-Lasertec; lasered extension slots for considerably lower

noise-level compared to conventional ciruclar saw blades

• LWZ = longitudinal section alternating tooth

Technical Data

Cut Standard Pinhole drilling

breadth blade quantity / Ø /

Article No. Article Description QTY thickness centre distance

3.2 2.2 2x7/42 + 2x9/46.4 + 2x10/60

5746 250 30 24 CIRC.SAW BLADE LWZ 250X30 24T 1

5746 300 30 24 CIRC.SAW BLADE LWZ 300X30 24T 1 3.2 2.2 2x7/42 + 2x9/46.4 + 2x10/60

3.2 2.2 2x7/42 + 2x9/46.4 + 2x10/60

5746 300 30 28 CIRC.SAW BLADE LWZ 300X30 28T 1

5746 315 30 28 CIRC.SAW BLADE LWZ 315X30 28T 1 3.2 2.2 2x7/42 + 2x9/46.4 + 2x10/60

5746 350 30 24 CIRC.SAW BLADE LWZ 350X30 24T 1 3.5 2.5 2x7/42 + 2x9/46.4 + 2x10/60

5746 350 30 32 CIRC.SAW BLADE LWZ 350X30 32T 1 3.5 2.5 2x7/42 + 2x9/46.4 + 2x10/60

5746 400 30 28 CIRC.SAW BLADE LWZ 400X30 28T 1 3.5 2.5 2x7/42 + 2x9/46.4 + 2x10/60

3.5 2.5 2x7/42 + 2x9/46.4 + 2x10/60

5746 400 30 36 CIRC.SAW BLADE LWZ 400X30 36T 1

5746 450 30 40 CIRC.SAW BLADE LWZ 450X30 40T 1 4.5 2.8 2x7/42 + 2x9/46.4 + 2x10/60

(Blade-Ø mm x drill-Ø mm / number of teeth)

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 488