Page 39 - Industrial Tools Catalog (1)

P. 39

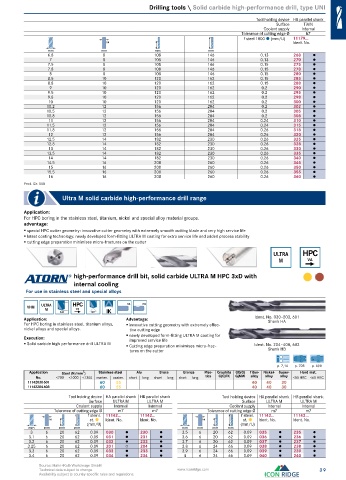

Drilling tools \ Solid carbide high-performance drill, type UNI

Tool holding device HB parallel shank

Surface TiAlN

Coolant supply Internal

Tolerance of cutting edge Ø h7

f steel 1000 (mm/U) 11179...

h6 Ident. No.

mm mm mm mm

6.8 8 108 146 0.13 268 ●

7 8 108 146 0.13 270 ●

7.5 8 108 146 0.15 275 ●

7.8 8 108 146 0.15 278 ●

8 8 108 146 0.15 280 ●

8.5 10 120 162 0.15 285 ●

8.8 10 120 162 0.15 288 ●

9 10 120 162 0.2 290 ●

9.5 10 120 162 0.2 295 ●

9.8 10 120 162 0.2 298 ●

10 10 120 162 0.2 300 ●

10.2 12 156 204 0.2 302 ●

10.5 12 156 204 0.2 305 ●

10.8 12 156 204 0.2 308 ●

11 12 156 204 0.24 310 ●

11.5 12 156 204 0.24 315 ●

11.8 12 156 204 0.26 318 ●

12 12 156 204 0.26 320 ●

12.5 14 182 230 0.26 325 ●

12.8 14 182 230 0.26 328 ●

13 14 182 230 0.26 330 ●

13.5 14 182 230 0.26 335 ●

14 14 182 230 0.26 340 ●

14.5 16 208 260 0.26 345 ●

15 16 208 260 0.26 350 ●

15.5 16 208 260 0.26 355 ●

16 16 208 260 0.26 360 ●

Prod. Gr. 140

Ultra M solid carbide high-performance drill range

Application:

For HPC boring in the stainless steel, titanium, nickel and special alloy material groups.

advantage:

special HPC cutter geometry: innovative cutter geometry with extremely smooth cutting blade and very high service life

latest coating technology: newly developed form-fitting ULTRA M coating for extra service life and added process stability

cutting edge preparation minimises micro-fractures on the cutter

ULTRA HPC

M VA

high-performance drill bit, solid carbide ULTRA M HPC 3xD with

internal cooling

For use in stainless steel and special alloys

VHM ULTRA HPC HA HB

M VA IK

3xD 140°

Application: Advantage: Ident. No. 030–203, 601

Shank HA

For HPC boring in stainless steel, titanium alloys, innovative cutting geometry with extremely effec-

nickel alloys and special alloys. tive cutting edge

Execution: newly developed form-fitting ULTRA M coating for

improved service life

Solid carbide high-performance drill ULTRA M Cutting edge preparation minimises micro-frac- Ident. No. 204–400, 602

tures on the cutter Shank HB

p. 7,14 p. 705 p. 698

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11142030-601 60 55 40 40 30

11142204-603 60 55 40 40 30

Tool holding device HA parallel shank HB parallel shank Tool holding device HA parallel shank HB parallel shank

Surface ULTRA M ULTRA M Surface ULTRA M ULTRA M

Coolant supply Internal Internal Coolant supply Internal Internal

Tolerance of cutting edge Ø m7 m7 Tolerance of cutting edge Ø m7 m7

f steinl. 11142... 11142... f steinl. 11142... 11142...

h6 st. Ident. No. Ident. No. h6 st. Ident. No. Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

3 6 20 62 0.09 030 ● 230 ● 3.5 6 20 62 0.09 035 ● 235 ●

3.1 6 20 62 0.09 031 ● 231 ● 3.6 6 20 62 0.09 036 ● 236 ●

3.2 6 20 62 0.09 032 ● 232 ● 3.7 6 20 62 0.09 037 ● 237 ●

3.25 6 20 62 0.09 201 ○ 204 ● 3.8 6 24 66 0.09 038 ● 238 ●

3.3 6 20 62 0.09 033 ● 233 ● 3.9 6 24 66 0.09 039 ● 239 ●

3.4 6 20 62 0.09 034 ● 234 ● 4 6 24 66 0.09 040 ● 240 ●

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com 39

Availability subject to country specific rules and regulations.