Page 42 - Industrial Tools Catalog (1)

P. 42

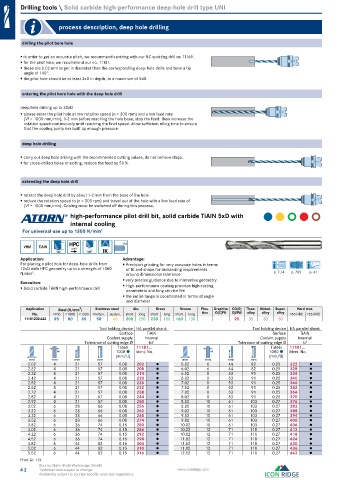

Drilling tools \ Solid carbide high-performance deep-hole drill type UNI

process description, deep hole drilling

drilling the pilot bore hole

in order to get an accurate pitch, we recommend centring with our NC spotting drill no 11169.

for the pilot hole, we recommend our no. 11181.

these are 0.02 mm larger in diameter than the corresponding deep-hole drills and have a tip

angle of 140°.

the pilot hole should be at least 3xD in depth, to a maximum of 5xD.

entering the pilot bore hole with the deep hole drill

deep hole drilling up to 30xD

please enter the pilot hole at low rotation speed (n = 300 rpm) and a low feed rate

(Vf = 1000 mm/min), 1-2 mm before reaching the hole base, stop the feed. then increase the

rotation speed continuously until reaching the final speed. allow sufficient idling time to ensure

that the cooling pump has built up enough pressure.

deep hole drilling

carry out deep hole drilling with the recommended cutting values, do not remove chips.

for cross-drilled holes or exiting, reduce the feed by 50 %.

extending the deep hole drill

retract the deep hole drill by about 1-2 mm from the base of the hole

reduce the rotation speed to (n = 300 rpm) and travel out of the hole with a low feed rate of

(Vf = 1000 mm/min). Cooling must be switched off during this process.

high-performance pilot drill bit, solid carbide TiAlN 5xD with

internal cooling

For universal use up to 1300 N/mm 2

HPC HA

VHM TiAlN

UNI

5xD 140° IK

Application: Advantage:

For placing a pilot hole for deep-hole drills from Precision grinding for very accurate holes in terms

12xD with HPC geometry up to a strength of 1300 of fit and shape for demanding requirements

N/mm . 2 around dimensional tolerance p. 7,14 p. 705 p. 41

Execution: very precise guidance due to innovative geometry

Solid carbide TiAlN high-performance drill High-performance coating provides high cutting

parameters and long service life

the entire range is coordinated in terms of angle

and diameter

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11181202-442 95 80 65 50 40 200 250 230 180 160 130 95 35 30 30

Tool holding device HA parallel shank Tool holding device HA parallel shank

Surface TiAlN Surface TiAlN

Coolant supply Internal Coolant supply Internal

Tolerance of cutting edge Ø h7 Tolerance of cutting edge Ø h7

f steel 11181... f steel 11181...

h6 1000 Ident. No. h6 1000 Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm mm mm

2.02 4 21 57 0.08 202 ● 5.82 6 44 82 0.25 322 ●

2.22 4 21 57 0.08 208 ● 6.02 6 44 82 0.25 328 ●

2.32 4 21 57 0.08 214 ● 6.52 8 53 91 0.25 334 ●

2.42 4 21 57 0.08 220 ● 6.82 8 53 91 0.25 340 ●

2.52 4 21 57 0.08 226 ● 7.02 8 53 91 0.25 346 ●

2.62 4 21 57 0.08 232 ● 7.52 8 53 91 0.25 352 ●

2.72 4 21 57 0.08 238 ● 7.82 8 53 91 0.25 364 ●

2.82 4 21 57 0.08 244 ● 8.02 8 53 91 0.25 370 ●

2.92 4 21 57 0.08 250 ● 8.52 10 61 103 0.27 376 ●

3.02 6 28 66 0.08 256 ● 8.82 10 61 103 0.27 382 ●

3.22 6 28 66 0.08 262 ● 9.02 10 61 103 0.27 388 ●

3.32 6 28 66 0.08 268 ● 9.52 10 61 103 0.27 394 ●

3.52 6 28 66 0.08 274 ● 9.82 10 61 103 0.27 400 ●

3.82 6 36 74 0.15 280 ● 10.02 10 61 103 0.27 406 ●

4.02 6 36 74 0.15 286 ● 10.22 12 71 118 0.27 412 ●

4.22 6 36 74 0.15 292 ● 10.82 12 71 118 0.27 418 ●

4.52 6 36 74 0.15 298 ● 11.02 12 71 118 0.27 424 ●

4.82 6 44 82 0.15 304 ● 11.52 12 71 118 0.27 430 ●

5.02 6 44 82 0.15 310 ● 11.82 12 71 118 0.27 436 ●

5.52 6 44 82 0.15 316 ● 12.02 12 71 118 0.27 442 ●

Prod. Gr. 113

Source: Hahn+Kolb Werkzeuge GmbH

42 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.