Page 287 - Icon Ridge Presents ATORN

P. 287

Milling tools monoblock \ Technical introduction – monobloc milling

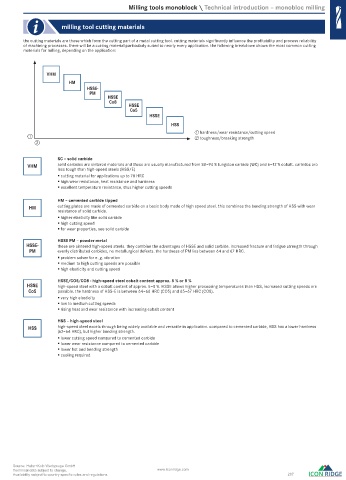

milling tool cutting materials

the cutting materials are those which form the cutting part of a metal cutting tool. cutting materials significantly influence the profitability and process reliability

of machining processes. there will be a cutting material particularly suited to nearly every application. the following breakdown shows the most common cutting

materials for milling, depending on the application:

VHM

HM

HSSE-

PM

HSSE

Co8

HSSE

Co5

HSSE

HSS

① hardness/wear resistance/cutting speed

1 ② toughness/breaking strength

2

SC – solid carbide

VHM solid carbides are sintered materials and these are usually manufactured from 88–94 % tungsten carbide (WC) and 6–12 % cobalt. carbides are

less tough than high-speed steels (HSS/E)

cutting material for applications up to 70 HRC

high wear resistance, heat resistance and hardness

excellent temperature resistance, thus higher cutting speeds

HM – cemented carbide tipped

HM cutting plates are made of cemented carbide on a basic body made of high speed steel. this combines the bending strength of HSS with wear

resistance of solid carbide.

higher elasticity like solid carbide

high cutting speed

for wear properties, see solid carbide

HSSE PM – powder metal

HSSE- these are sintered high-speed steels. they combine the advantages of HSSE and solid carbide. increased fracture and fatigue strength through

PM evenly distributed carbides, no metallurgical defects. the hardness of PM lies between 64 and 67 HRC.

problem solver for e. g. vibration

medium to high cutting speeds are possible

high elasticity and cutting speed

HSSE/CO5/CO8 - high-speed steel cobalt content approx. 5 % or 8 %

HSSE high-speed steel with a cobalt content of approx. 5–8 %. HSSE allows higher processing temperatures than HSS, increased cutting speeds are

Co5 possible. the hardness of HSS-E is between 64–66 HRC (CO5) and 65–67 HRC (CO8).

very high elasticity

low to medium cutting speeds

rising heat and wear resistance with increasing cobalt content

HSS – high-speed steel

HSS high-speed steel excels through being widely available and versatile in application. compared to cemented carbide, HSS has a lower hardness

(62–64 HRC), but higher bending strength.

lower cutting speed compared to cemented carbide

lower wear resistance compared to cemented carbide

lower hot and bending strength

cooling required

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 287

0337_EN_2018_KERN[21847558]-j.indd 339 12/17/2018 3:32:20 PM