Page 289 - Icon Ridge Presents ATORN

P. 289

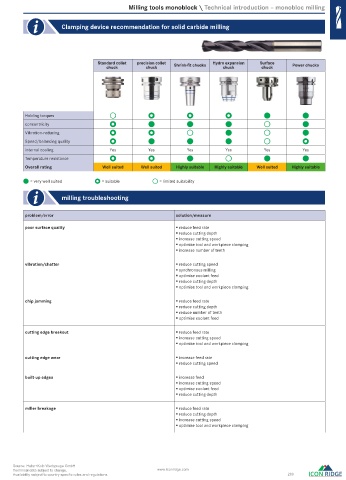

Milling tools monoblock \ Technical introduction – monobloc milling

Clamping device recommendation for solid carbide milling

Standard collet precision collet Shrink-fi t chucks Hydro expansion Surface Power chucks

chuck chuck chuck chuck

Holding torques

concentricity

Vibration-reducing

Speed/balancing quality

internal cooling Yes Yes Yes Yes Yes Yes

Temperature resistance

Overall rating Well suited Well suited Highly suitable Highly suitable Well suited Highly suitable

= very well suited = suitable = limited suitability

milling troubleshooting

problem/error solution/measure

poor surface quality reduce feed rate

reduce cutting depth

increase cutting speed

optimise tool and workpiece clamping

increase number of teeth

vibration/chatter reduce cutting speed

synchronous milling

optimise coolant feed

reduce cutting depth

optimise tool and workpiece clamping

chip jamming reduce feed rate

reduce cutting depth

reduce number of teeth

optimise coolant feed

cutting edge breakout reduce feed rate

increase cutting speed

optimise tool and workpiece clamping

cutting edge wear increase feed rate

reduce cutting speed

built-up edges increase feed

increase cutting speed

optimise coolant feed

reduce cutting depth

miller breakage reduce feed rate

reduce cutting depth

increase cutting speed

optimise tool and workpiece clamping

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 289

0340_EN_2018_KERN[21847562]-g.indd 341 12/17/2018 3:32:29 PM