Page 358 - Icon Ridge Presents ATORN

P. 358

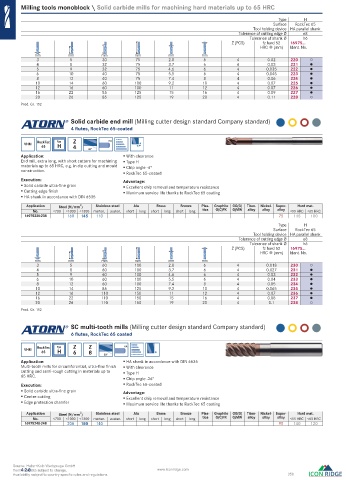

Milling tools monoblock \ Solid carbide mills for machining hard materials up to 65 HRC

Type H

Surface RockTec 65

Tool holding device HA parallel shank

Tolerance of cutting edge Ø e8

Tolerance of shank Ø h6

Z (PCS) fz hard 52 16975...

HRC (mm) Ident. No.

mm mm mm mm mm mm

3 5 30 75 2.8 6 4 0.02 220 ○

4 8 32 75 3.7 6 4 0.03 221

5 9 32 75 4.6 6 4 0.035 222

6 10 40 75 5.5 6 4 0.045 223

8 12 40 75 7.4 8 4 0.06 224

10 14 60 100 9.2 10 4 0.07 225

12 16 60 100 11 12 4 0.07 226

16 22 85 125 15 16 4 0.09 227

20 26 85 125 19 20 4 0.11 228 ○

Prod. Gr. 152

Solid carbide end mill ( Milling cutter design standard Company standard )

4 fl utes, RockTec 65-coated

VHM RockTec Typ Z HA

65 H 4

Application: With clearance

End mill, extra long, with short cutters for machining Type H

materials up to 65 HRC, e.g. in dip cutting and mould Chip angle -6°

construction. RockTec 65-coated

Execution: Advantage:

Solid carbide ultra-fi ne grain Excellent chip removal and temperature resistance

Cutting edge fi nish Maximum service life thanks to RockTec 65 coating

HA shank in accordance with DIN 6535

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16975230-238 160 145 110 75 115 100

Type H

Surface RockTec 65

Tool holding device HA parallel shank

Tolerance of cutting edge Ø e8

Tolerance of shank Ø h6

Z (PCS) fz hard 52 16975...

HRC (mm) Ident. No.

mm mm mm mm mm mm

3 5 60 100 2.8 6 4 0.018 230 ○

4 8 60 100 3.7 6 4 0.027 231

5 9 60 100 4.6 6 4 0.03 232

6 10 60 100 5.5 6 4 0.04 233

8 12 60 100 7.4 8 4 0.05 234

10 14 85 125 9.2 10 4 0.065 235

12 16 110 150 11 12 4 0.07 236

16 22 110 150 15 16 4 0.08 237

20 26 110 150 19 20 4 0.1 238 ○

Prod. Gr. 152

SC multi-tooth mills ( Milling cutter design standard Company standard )

6 fl utes, RockTec 65 coated

VHM RockTec Typ Z Z HA

H

65 6 8

Application: HA shank in accordance with DIN 6535

Multi-tooth mills for circumferential, ultra-fi ne fi nish With clearance

cutting and semi-rough cutting in materials up to Type H

65 HRC.

Chip angle -26°

Execution: RockTec 65-coated

Solid carbide ultra-fi ne grain Advantage:

Centre cutting Excellent chip removal and temperature resistance

Edge protection chamfer Maximum service life thanks to RockTec 65 coating

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16975240-248 200 180 140 95 140 120

Source: Hahn+Kolb Werkzeuge GmbH

428

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 358

0420_EN_2018_KERN[21847683]-n.indd 428 12/17/2018 3:32:51 PM