Page 360 - Icon Ridge Presents ATORN

P. 360

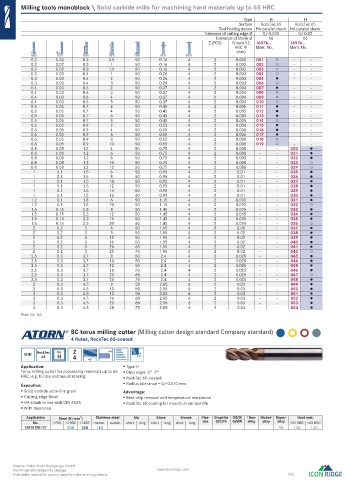

Milling tools monoblock \ Solid carbide mills for machining hard materials up to 65 HRC

Type H H

Surface RockTec 65 RockTec 65

Tool holding device HA parallel shank HA parallel shank

Tolerance of cutting edge Ø 0/-0.012 0/-0.02

Tolerance of shank Ø h6 h6

Z (PCS) fz hard 52 16976... 16976...

HRC Ident. No. Ident. No.

(mm)

mm mm mm mm mm mm mm

0.2 0.02 0.3 0.5 50 0.16 4 2 0.002 001 ○ - -

0.2 0.02 0.3 1 50 0.16 4 2 0.002 002 ○ - -

0.2 0.02 0.3 1.5 50 0.16 4 2 0.002 003 ○ - -

0.3 0.03 0.4 1 50 0.26 4 2 0.003 004 ○ - -

0.3 0.03 0.4 2 50 0.26 4 2 0.003 005 - -

0.3 0.03 0.4 3 50 0.26 4 2 0.003 006 ○ - -

0.4 0.03 0.6 2 50 0.37 4 2 0.004 007 - -

0.4 0.03 0.6 3 50 0.37 4 2 0.004 008 ○ - -

0.4 0.03 0.6 4 50 0.37 4 2 0.004 009 ○ - -

0.4 0.03 0.6 5 50 0.37 4 2 0.004 010 ○ - -

0.5 0.05 0.7 2 50 0.45 4 2 0.005 011 - -

0.5 0.05 0.7 4 50 0.45 4 2 0.005 012 - -

0.5 0.05 0.7 6 50 0.45 4 2 0.005 013 - -

0.5 0.05 0.7 8 50 0.45 4 2 0.005 014 ○ - -

0.6 0.05 0.9 2 50 0.55 4 2 0.006 015 - -

0.6 0.05 0.9 4 50 0.55 4 2 0.006 016 - -

0.6 0.05 0.9 6 50 0.55 4 2 0.006 017 - -

0.6 0.05 0.9 8 50 0.55 4 2 0.006 018 ○ - -

0.6 0.05 0.9 10 50 0.55 4 2 0.006 019 ○ - -

0.8 0.08 1.2 4 50 0.75 4 2 0.008 - - 020

0.8 0.08 1.2 6 50 0.75 4 2 0.008 - - 021

0.8 0.08 1.2 8 50 0.75 4 2 0.008 - - 022

0.8 0.08 1.2 10 50 0.75 4 2 0.008 - - 023 ○

0.8 0.08 1.2 12 50 0.75 4 2 0.008 - - 024 ○

1 0.1 1.5 6 50 0.95 4 2 0.01 - - 025

1 0.1 1.5 8 50 0.95 4 2 0.01 - - 026

1 0.1 1.5 10 50 0.95 4 2 0.01 - - 027

1 0.1 1.5 12 50 0.95 4 2 0.01 - - 028

1 0.1 1.5 14 50 0.95 4 2 0.01 - - 029

1 0.1 1.5 16 60 0.95 4 2 0.01 - - 030

1.2 0.1 1.8 6 50 1.15 4 2 0.012 - - 031

1.2 0.1 1.8 10 50 1.15 4 2 0.012 - - 032 ○

1.5 0.15 2.3 8 50 1.45 4 2 0.015 - - 033

1.5 0.15 2.3 12 50 1.45 4 2 0.015 - - 034

1.5 0.15 2.3 16 50 1.45 4 2 0.015 - - 035

1.5 0.15 2.3 20 60 1.45 4 2 0.015 - - 036 ○

2 0.2 3 6 50 1.95 4 2 0.02 - - 037

2 0.2 3 8 50 1.95 4 2 0.02 - - 038

2 0.2 3 12 50 1.95 4 2 0.02 - - 039

2 0.2 3 16 50 1.95 4 2 0.02 - - 040

2 0.2 3 20 60 1.95 4 2 0.02 - - 041

2 0.2 3 25 75 1.95 4 2 0.02 - - 042 ○

2.5 0.3 3.7 8 50 2.4 4 2 0.025 - - 043

2.5 0.3 3.7 10 50 2.4 4 2 0.025 - - 044

2.5 0.3 3.7 12 50 2.4 4 2 0.025 - - 045

2.5 0.3 3.7 16 50 2.4 4 2 0.025 - - 046

2.5 0.3 3.7 20 60 2.4 4 2 0.025 - - 047 ○

2.5 0.3 3.7 25 75 2.4 4 2 0.025 - - 048

3 0.3 4.5 8 50 2.85 6 2 0.03 - - 049

3 0.3 4.5 10 50 2.85 6 2 0.03 - - 050

3 0.3 4.5 12 50 2.85 6 2 0.03 - - 051

3 0.3 4.5 16 60 2.85 6 2 0.03 - - 052

3 0.3 4.5 20 60 2.85 6 2 0.03 - - 053

3 0.3 4.5 25 75 2.85 6 2 0.03 - - 054

Prod. Gr. 152

SC torus milling cutter ( Milling cutter design standard Company standard )

4 fl utes, RockTec 65-coated

VHM RockTec Typ Z HA

65 H 4

Application: Type H

Torus milling cutter for processing materials up to 65 Chip angle -5° -7°

HRC, e.g. for die and mould making. RockTec 65-coated

Execution: Radius tolerance = 0/-0.010 mm

Solid carbide ultra-fi ne grain Advantage:

Cutting edge fi nish Best chip removal and temperature resistance

HA shank in line with DIN 6535 RockTec 65 coating for maximum service life

With clearance

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16976100-127 200 180 140 95 140 120

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 360

0420_EN_2018_KERN[21847683]-n.indd 430 12/17/2018 3:32:54 PM