Page 359 - Icon Ridge Presents ATORN

P. 359

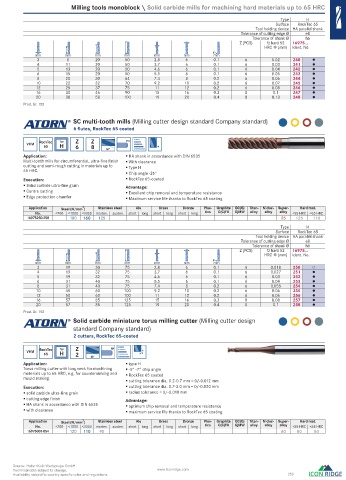

Milling tools monoblock \ Solid carbide mills for machining hard materials up to 65 HRC

Type H

Surface RockTec 65

Tool holding device HA parallel shank

Tolerance of cutting edge Ø e8

Tolerance of shank Ø h6

Z (PCS) fz hard 52 16975...

HRC (mm) Ident. No.

mm mm mm mm mm mm mm

3 8 20 50 2.8 6 0.1 6 0.02 240

4 11 20 50 3.7 6 0.1 6 0.03 241

5 13 20 50 4.6 6 0.1 6 0.04 242

6 15 20 50 5.5 6 0.1 6 0.05 243

8 20 30 64 7.4 8 0.2 6 0.06 244

10 22 32 70 9.2 10 0.2 6 0.07 245

12 25 37 75 11 12 0.2 6 0.08 246

16 30 46 90 15 16 0.3 8 0.1 247

20 38 58 100 19 20 0.4 8 0.13 248

Prod. Gr. 152

SC multi-tooth mills ( Milling cutter design standard Company standard )

6 fl utes, RockTec 65 coated

VHM RockTec Typ Z Z HA

65 H 6 8

Application: HA shank in accordance with DIN 6535

Multi-tooth mills for circumferential, ultra-fi ne fi nish With clearance

cutting and semi-rough cutting in materials up to Type H

65 HRC. Chip angle -26°

Execution: RockTec 65-coated

Solid carbide ultra-fi ne grain Advantage:

Centre cutting Excellent chip removal and temperature resistance

Edge protection chamfer Maximum service life thanks to RockTec 65 coating

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16975250-258 180 160 125 85 125 110

Type H

Surface RockTec 65

Tool holding device HA parallel shank

Tolerance of cutting edge Ø e8

Tolerance of shank Ø h6

Z (PCS) fz hard 52 16975...

HRC (mm) Ident. No.

mm mm mm mm mm mm mm

3 19 30 75 2.8 6 0.1 6 0.018 250 ○

4 19 32 75 3.7 6 0.1 6 0.027 251

5 19 32 75 4.6 6 0.1 6 0.03 252

6 31 40 75 5.5 6 0.1 6 0.04 253

8 31 40 75 7.4 8 0.2 6 0.055 254

10 45 60 100 9.2 10 0.2 6 0.06 255

12 50 60 100 11 12 0.2 6 0.06 256

16 57 85 125 15 16 0.3 8 0.08 257

20 57 85 125 19 20 0.4 8 0.1 258

Prod. Gr. 152

Solid carbide miniature torus milling cutter ( Milling cutter design

standard Company standard )

2 cutters, RockTec 65-coated

RockTec Typ Z HA

VHM H

65 2

Application: type H

Torus milling cutter with long neck for machining -5° -7° chip angle

materials up to 65 HRC, e.g. for countersinking and RockTec 65 coated

mould making. cutting tolerance dia. 0.2-0.7 mm = 0/-0.012 mm

Execution: cutting tolerance dia. 0.7-3.0 mm = 0/-0.020 mm

solid carbide ultra-fi ne grain radius tolerance = 0/-0.010 mm

cutting edge fi nish Advantage:

HA shank in accordance with DIN 6535 optimum chip removal and temperature resistance

with clearance maximum service life thanks to RockTec 65 coating

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

16976001-054 120 110 95 60 80 80

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 359

0420_EN_2018_KERN[21847683]-n.indd 429 12/17/2018 3:32:53 PM