Page 477 - Icon Ridge Presents ATORN

P. 477

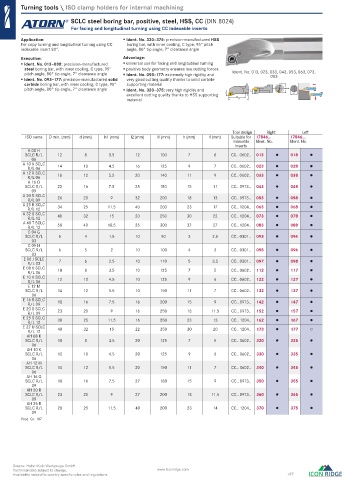

Turning tools \ ISO clamp holders for internal machining

SCLC steel boring bar, positive, steel, HSS, CC ( DIN 8024 )

For facing and longitudinal turning using CC indexable inserts

Application: Ident. No. 320–375: precision-manufactured HSS

For copy turning and longitudinal turning using CC boring bar, with inner cooling, C type, 95° pitch

indexable insert 80°. angle, 80° tip angle, 7° clearance angle

Execution: Advantage:

Ident. No. 013–088: precision-manufactured universal use for facing and longitudinal turning

steel boring bar, with inner cooling, C type, 95° positive body geometry ensures low cutting forces

pitch angle, 80° tip angle, 7° clearance angle Ident. No. 093–177: extremely high rigidity and Ident. No. 013, 023, 033, 043, 053, 063, 073,

083

Ident. No. 093–177: precision-manufactured solid very good cutting quality thanks to solid carbide

carbide boring bar, with inner cooling, C type, 95° supporting material d

pitch angle, 80° tip angle, 7° clearance angle Ident. No. 320–375: very high rigidity and h1 ØDmin.

excellent cutting quality thanks to HSS supporting f l2 h

material l1

Tool design Right Le

ISO name D min. (mm) d (mm) h1 (mm) l2 (mm) l1 (mm) h (mm) f (mm) Suitable for 17846... 17846...

indexable Ident. No. Ident. No.

inserts

A 08 H

SCLC R/L 12 8 3.5 12 100 7 6 CC.. 0602.. 013 018

06

A 10 K SCLC 14 10 4.5 16 125 9 7 CC.. 0602.. 023 028

R/L 06

A 12 R SCLC 18 12 5.5 20 140 11 9 CC.. 0602.. 033 038

R/L 06

A 16 Q

SCLC R/L 22 16 7.5 25 180 15 11 CC.. 09T3.. 043 048

09

A 20 R SCLC 053 058

R/L 09 26 20 9 32 200 18 13 CC.. 09T3..

A 25 R SCLC 063 068

R/L 12 34 25 11.5 40 200 23 17 CC.. 1204..

A 32 S SCLC 073 078

R/L 12 40 32 15 20 250 30 22 CC.. 1204..

A 40 T SCLC 083 088

R/L 12 50 40 18.5 25 300 37 27 CC.. 1204..

C 04 G

SCLC R/L 5 4 1.5 10 90 3 2.5 CC.. 0301.. 093 094

03

C 05 H

SCLC R/L 6 5 2 10 100 4 3 CC.. 0301.. 095 096

03

E 06 J SCLC 097 098

R/L 03 7 6 2.5 10 110 5 3.5 CC.. 0301..

E 08 K SCLC 112 117

R/L 06 10 8 3.5 10 125 7 5 CC.. 0602..

E 10 K SCLC 122 127

R/L 06 12 10 4.5 10 125 9 6 CC.. 0602..

E 12 M

SCLC R/L 14 12 5.5 10 150 11 7 CC.. 0602.. 132 137

06

E 16 R SCLC 18 16 7.5 16 200 15 9 CC.. 09T3.. 142 147

R/L 09

E 20 S SCLC 23 20 9 16 250 18 11.5 CC.. 09T3.. 152 157

R/L 09

E 25 S SCLC 30 25 11.5 16 250 23 13 CC.. 1204.. 162 167

R/L 12

E 32 U SCLC 40 32 15 22 350 30 20 CC.. 1204.. 173 177 ○

R/L 12

AH 08 K

SCLC R/L 10 8 3.5 20 125 7 5 CC.. 0602.. 320 325

06

AH 10 K

SCLC R/L 12 10 4.5 20 125 9 6 CC.. 0602.. 330 335

06

AH 12 M

SCLC R/L 14 12 5.5 20 150 11 7 CC.. 0602.. 340 345

06

AH 16 Q

SCLC R/L 18 16 7.5 27 180 15 9 CC.. 09T3.. 350 355

09

AH 20 R

SCLC R/L 23 20 9 27 200 18 11.5 CC.. 09T3.. 360 365

09

AH 25 R

SCLC R/L 28 25 11.5 40 200 23 14 CC.. 1204.. 370 375

09

Prod. Gr. 107

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 477

0609_EN_2018_KERN[21847923]-g.indd 610 12/17/2018 3:33:15 PM