Page 479 - Icon Ridge Presents ATORN

P. 479

Turning tools \ ISO clamp holders for internal machining

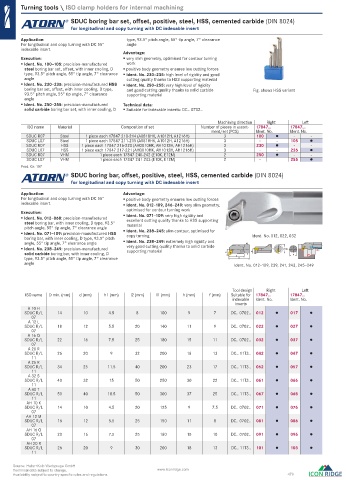

SDUC boring bar set, off set, positive, steel, HSS, cemented carbide ( DIN 8024 )

for longitudinal and copy turning with DC indexable insert

Application: type, 93.5° pitch angle, 55° tip angle, 7° clearance

For longitudinal and copy turning with DC 55° angle

indexable insert.

Advantage:

Execution: very slim geometry, optimised for contour turning

Ident. No. 100–105: precision-manufactured work

steel boring bar set, off set, with inner cooling, D positive body geometry ensures low cutting forces

type, 93.5° pitch angle, 55° tip angle, 7° clearance Ident. No. 230–235: high level of rigidity and good

angle cutting quality thanks to HSS supporting material

Ident. No. 230–235: precision-manufactured HSS Ident. No. 250–255: very high level of rigidity

boring bar set, off set, with inner cooling, D type, and good cutting quality thanks to solid carbide Fig. shows HSS variant

93.5° pitch angle, 55° tip angle, 7° clearance supporting material

angle

Ident. No. 250–255: precision-manufactured Technical data:

solid carbide boring bar set, with inner cooling, D Suitable for indexable inserts: DC.. 0702..

Machining direction Right Le

ISO name Material Composition of set Number of pieces in assort- 17847... 17847...

ment/set (PCS) Ident. No. Ident. No.

SDUC R07 Steel 1 piece each 17847 210-214 (A0810HK, A1012H, A1216H) 3 100 - -

SDUC L07 Steel 1 piece each 17847 211-215 (A0810HK, A1012H, A1216H) 3 - - 105

SDUC R07 HSS 1 piece each 17847 216-220 (AH0810HK, AH1012H, AH1216H) 3 230 - -

SDUC L07 HSS 1 piece each 17847 217-221 (AH0810HK, AH1012H, AH1216H) 3 - - 235

SDUC R07 VHM 1 piece each 17847 240-242 (E10K, E12M) 2 250 - -

SDUC L07 VHM 1 piece each 17847 241-243 (E10K, E12M) 2 - - 255

Prod. Gr. 107

SDUC boring bar, off set, positive, steel, HSS, cemented carbide ( DIN 8024 )

for longitudinal and copy turning with DC indexable insert

Application: Advantage:

For longitudinal and copy turning with DC 55° positive body geometry ensures low cutting forces

indexable insert. Ident. No. 012–109, 246–249: very slim geometry,

Execution: optimised for contour turning work

Ident. No. 012–068: precision-manufactured Ident. No. 071–109: very high rigidity and

excellent cutting quality thanks to HSS supporting

steel boring bar, with inner cooling, D type, 93.5° material

pitch angle, 55° tip angle, 7° clearance angle

Ident. No. 071–109: precision-manufactured HSS Ident. No. 238–245: slim contour, optimised for Ident. No. 012, 022, 032

copy turning

boring bar, with inner cooling, D type, 93.5° pitch

angle, 55° tip angle, 7° clearance angle Ident. No. 238–249: extremely high rigidity and d

Ident. No. 238–249: precision-manufactured very good cutting quality thanks to solid carbide ØDmin.

supporting material

solid carbide boring bar, with inner cooling, D f1 h1 H

type, 93.5° pitch angle, 55° tip angle, 7° clearance l1 l2

angle Ident. No. 012–109, 239, 241, 243, 245–249

Tool design Right Le

ISO name D min. (mm) d (mm) h1 (mm) l2 (mm) l1 (mm) h (mm) f (mm) Suitable for 17847... 17847...

indexable Ident. No. Ident. No.

inserts

A 10 H

SDUC R/L 14 10 4.5 8 100 9 7 DC.. 0702.. 012 017

07

A 12 L

SDUC R/L 18 12 5.5 20 140 11 9 DC.. 0702.. 022 027

07

A 16 Q

SDUC R/L 22 16 7.5 25 180 15 11 DC.. 0702.. 032 037

07

A 20 R

SDUC R/L 26 20 9 32 200 18 13 DC.. 11T3.. 042 047

11

A 25 R

SDUC R/L 34 25 11.5 40 200 23 17 DC.. 11T3.. 052 057

11

A 32 S

SDUC R/L 40 32 15 50 250 30 22 DC.. 11T3.. 061 066

11

A 40 T

SDUC R/L 50 40 18.5 50 300 37 25 DC.. 11T3.. 067 068

11

AH 10 K

SDUC R/L 14 10 4.5 20 125 9 7.5 DC.. 0702.. 071 076

07

AH 12 M

SDUC R/L 16 12 5.5 25 150 11 8 DC.. 0702.. 081 086

07

AH 16 Q

SDUC R/L 20 16 7.5 25 180 15 10 DC.. 0702.. 091 096

07

AH 20 R

SDUC R/L 26 20 9 30 200 18 13 DC.. 11T3.. 101 103

11

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 479

0612_EN_2018_KERN[21847927]-h.indd 612 12/17/2018 3:33:08 PM