Page 522 - Icon Ridge Presents ATORN

P. 522

Turning tools \ Thread-cutting range

Thread-cutting range

For demanding serial users

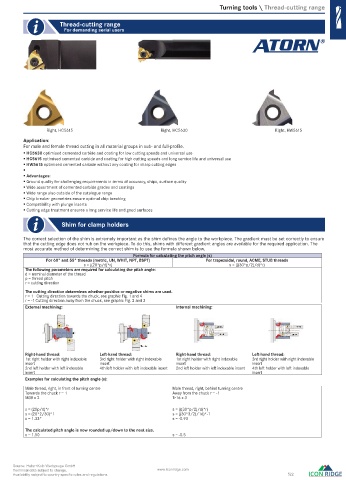

Right, HC5615 Right, HC5630 Right, HW5615

Application:

For male and female thread cutting in all material groups in sub- and full-profile.

HC5630 optimised cemented carbide and coating for low cutting speeds and universal use

HC5615 optimised cemented carbide and coating for high cutting speeds and long service life and universal use

HW5615 optimised cemented carbide without any coating for sharp cutting edges

Advantages:

Ground quality for challenging requirements in terms of accuracy, chips, surface quality

Wide assortment of cemented carbide grades and coatings

Wide range also outside of the catalogue range

Chip breaker geometries ensure optimal chip breaking

Compatibility with plunge inserts

Cutting edge treatment ensures a long service life and good surfaces

Shim for clamp holders

The correct selection of the shim is extremely important as the shim defines the angle to the workpiece. The gradient must be set correctly to ensure

that the cutting edge does not rub on the workpiece. To do this, shims with different gradient angles are available for the required application. The

most accurate method of determining the correct shim is to use the formula shown below.

Formula for calculating the pitch angle (s)

For 60° and 55° threads (metric, UN, WHIT, NPT, BSPT) For trapezoidal, round, ACME, STUB threads

s = ((20*p/d)*r) s = (((30*p/2)/d)*r)

The following parameters are required for calculating the pitch angle:

d = nominal diameter of the thread

p = thread pitch

r = cutting direction

The cutting direction determines whether positive or negative shims are used.

r = 1 Cutting direction towards the chuck, see graphic Fig. 1 and 4

r = -1 Cutting direction away from the chuck, see graphic Fig. 2 and 3

External machining: Internal machining:

2 2

1

1

Right-hand thread: Left-hand thread: Right-hand thread: Left-hand thread:

1st right holder with right indexable 3rd right holder with right indexable 1st right holder with right indexable 3rd right holder with right indexable

insert insert insert insert

2nd left holder with left indexable 4th left holder with left indexable insert 2nd left holder with left indexable insert 4th left holder with left indexable

insert insert

Examples for calculating the pitch angle (s):

Male thread, right, in front of turning centre Male thread, right, behind turning centre

Towards the chuck r = 1 Away from the chuck r = -1

M30 x 2 Tr16 x 3

s = (20p/d)*r s = (((30*p/2)/d)*r)

s = (20*2/30)*1 s = ((30*3/2)/16)*-1

s = 1.33° s = -0.93

The calculated pitch angle is now rounded up/down to the next size.

s = 1.50 s = -0.5

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 522

0655_EN_2018_KERN[21847989]-i.indd 655 12/17/2018 3:33:38 PM