Page 527 - Icon Ridge Presents ATORN

P. 527

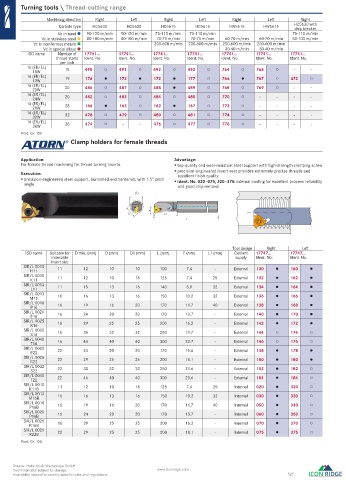

Turning tools \ Thread-cutting range

Machining direction Right Le Right Le Right Le Right

Carbide type HC5630 HC5630 HC5615 HC5615 HW5615 HW5615 HC5630 with

chip breaker

Vc in steel 90-120 m/min 90-120 m/min 75-110 m/min 75-110 m/min 75-110 m/min

Vc in stainless steel 80-100 m/min 80-100 m/min 70-75 m/min 70-75 m/min 60-70 m/min 60-70 m/min 80-100 m/min

Vc in non-ferrous metals 200-600 m/min 200-600 m/min 200-600 m/min 200-600 m/min

Vc in special alloys 30-40 m/min 30-40 m/min

ISO name Number of 17741... 17741... 17741... 17741... 17741... 17741... 17741...

thread starts Ident. No. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No. Ident. No.

per inch

16 (ER/EL) 490 491 492 493 764 765 -

18W 18 ○ ○ ○ ○ ○ ○ -

16 (ER/EL) 176 173 172 177 766 767 472

19W 19 ○ ○ ○

16 (ER/EL) 486 487 488 489 768 769 -

20W 20 ○ ○ ○ ○ ○ -

16 (ER/EL) 482 483 484 485 770 - -

24W 20 ○ ○ ○ ○ ○ - -

16 (ER/EL) 166 163 162 167 772 - -

28W 28 ○ ○ ○ - -

16 (ER/EL) 478 479 480 481 774 - -

32W 32 ○ ○ ○ ○ ○ - -

16 (ER/EL) 474 - 476 477 776 - -

36W 36 ○ - ○ ○ ○ - -

Prod. Gr. 158

Clamp holders for female threads

Application: Advantage:

For female thread machining for thread turning inserts. top-quality and wear-resistant steel support with high-strength clamping screw

Execution: precision-engineered insert seat provides extremely precise threads and

excellent fi nish quality

precision-engineered steel support, burnished and hardened, with 1.5° pitch Ident. No. 020–075, 320–375: internal cooling for excellent process reliability

angle and good chip removal

1

D1

F

D L1

L

Tool design Right Le

ISO name Suitable for D min. (mm) D (mm) D1 (mm) L (mm) F (mm) L1 (mm) Coolant 17747... 17747...

indexable supply Ident. No. Ident. No.

insert size

SIR/L 0010 11 12 10 10 100 7.4 - External 130 160

H11

SIR/L 0010 11 12 10 16 125 7.4 25 External 132 162

K11

SIR/L 0013 11 15 13 16 140 8.9 32 External 134 164

L11

SIR/L 0013 16 16 13 16 150 10.2 32 External 136 166

M16

SIR/L 0016 16 19 16 20 170 11.7 40 External 138 168

P16

SIR/L 0020 16 24 20 20 170 13.7 - External 140 170

P16

SIR/L 0025 16 29 25 25 200 16.2 - External 142 172

R16

SIR/L 0032 16 36 32 32 250 19.7 - External 144 ○ 174 ○

S16

SIR/L 0040 16 44 40 40 300 23.7 - External 146 ○ 176 ○

T16

SIR/L 0020 22 24 20 20 170 15.6 - External 148 178

P22

SIR/L 0025 22 29 25 25 200 18.1 - External 150 180

R22

SIR/L 0032 22 38 32 32 250 21.6 - External 152 182 ○

S22

SIR/L 0040 22 46 40 40 300 25.6 - External 154 184 ○

T22

SIR/L 0010 11 12 10 16 125 7.4 25 Internal 020 320 ○

K11B

SIR/L 0013 16 16 13 16 150 10.2 32 Internal 030 330 ○

M16B

SIR/L 0016 16 19 16 20 170 11.7 40 Internal 050 340 ○

P16B

SIR/L 0020 16 24 20 20 170 13.7 - Internal 060 350 ○

P16B

SIR/L 0025 16 29 25 25 200 16.2 - Internal 070 370 ○

R16B

SIR/L 0025 22 29 25 25 200 18.1 - Internal 075 375 ○

R22B

Prod. Gr. 158

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 527

0657_EN_2018_KERN[21847992]-n.indd 660 12/17/2018 3:33:46 PM