Page 545 - Icon Ridge Presents ATORN

P. 545

Turning tools \ Parting tools

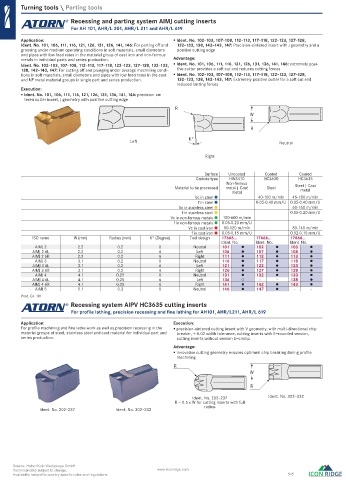

Recessing and parting system AIMJ cutting inserts

For AH 101, AHR/L 201, AHR/L 211 and AHR/L 619

Application: Ident. No. 102–103, 107–108, 112–113, 117–118, 122–123, 127–128,

Ident. No. 101, 106, 111, 116, 121, 126, 131, 136, 141, 146: For parting off and 132–133, 138, 142–143, 147: Precision-sintered insert with J geometry and a

grooving under medium operating conditions in so materials, small diameters positive cutting edge

and pipes with low feed rates in the material group of cast iron and non-ferrous

metals in individual parts and series production. Advantage:

Ident. No. 102–103, 107–108, 112–113, 117–118, 122–123, 127–128, 132–133, Ident. No. 101, 106, 111, 116, 121, 126, 131, 136, 141, 146: extremely posi-

138, 142–143, 147: For cutting off and plunging under average machining condi- tive cutter provides a so cut and reduces cutting forces

tions in so materials, small diameters and pipes with low feed rates in the cast Ident. No. 102–103, 107–108, 112–113, 117–118, 122–123, 127–128,

and NF metal material groups in single part and series production. 132–133, 138, 142–143, 147: Extremely positive cutter for a so cut and

reduced cutting forces

Execution:

Ident. No. 101, 106, 111, 116, 121, 126, 131, 136, 141, 146: precision-sin-

tered cutter insert, J geometry with positive cutting edge

R

W

R

Le K° Neutral

Right

Surface Uncoated Coated Coated

Carbide type HW3410 HC3630 HC3635

Non-ferrous

Material to be processed metal | Cast Steel Steel | Cast

metal metal

Vc in steel 40-150 m/min 45-180 m/min

f in steel 0.05-0.40 mm/U 0.05-0.40 mm/U

Vc in stainless steel 60-160 m/min

f in stainless steel 0.05-0.20 mm/U

Vc in non-ferrous metals 100-600 m/min

f in non-ferrous metals 0.05-0.20 mm/U

Vc in cast iron 80-120 m/min 80-140 m/min

f in cast iron 0.05-0.15 mm/U 0.02-0.15 mm/U

ISO name W (mm) Radius (mm) K° (Degree) Tool design 17666... 17666... 17666...

Ident. No. Ident. No. Ident. No.

AIMJ 2 2.2 0.2 0 Neutral 101 102 103

AIMJ 2 6L 2.2 0.2 6 Le 106 107 108

AIMJ 2 6R 2.2 0.2 6 Right 111 112 113

AIMJ 3 3.1 0.2 0 Neutral 116 117 118

AIMJ 3 6L 3.1 0.2 6 Le 121 122 123

AIMJ 3 6R 3.1 0.2 6 Right 126 127 128

AIMJ 4 4.1 0.25 0 Neutral 131 132 133

AIMJ 4 6L 4.1 0.25 6 Le 136 ○ - - 138

AIMJ 4 6R 4.1 0.25 6 Right 141 142 143

AIMJ 5 5.1 0.3 0 Neutral 146 147 - -

Prod. Gr. 181

Recessing system AIPV HC3635 cutting inserts

For profi le lathing, precision recessing and fi ne lathing for AH101, AHR/L211, AHR/L 619

Application: Execution:

For profi le machining and fi ne lathe work as well as precision recessing in the precision-sintered cutting insert with V geometry, with multi-directional chip

material groups of steel, stainless steel and cast material for individual part and breaker, +-0.02 width tolerance, cutting inserts with E=rounded version,

series production. cutting inserts without version E=circlip

Advantage:

innovative cutting geometry ensures optimum chip breaking during profi le

machining

R

W

R

Ident. No. 202–237 Ident. No. 302–332

R = 0.5 x W for cutting inserts with full

Ident. No. 202–237 Ident. No. 302–332 radius

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 545

0677_EN_2018_KERN[21848024]-j.indd 678 12/17/2018 3:33:57 PM