Page 550 - Icon Ridge Presents ATORN

P. 550

Tool clamp \ Technical introduction – tool chucks

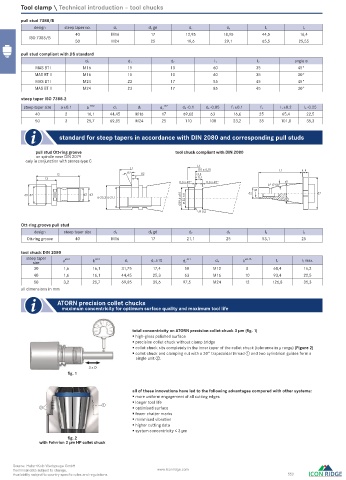

pull stud 7388/B

design steep taper no. d 2 d 3 g6 d 7 d 9 l 2 l 3

40 M16 17 12,95 18,95 44,5 16,4

ISO 7388/B

50 M24 25 19,6 29,1 65,5 25,55

pull stud compliant with JIS standard

angle α

d 5 d 1 d 2 l 1 l 2

MAS BT I M16 15 10 60 35 45°

MAS BT II M16 15 10 60 35 30°

MAS BT I M24 23 17 85 45 45°

MAS BT II M24 23 17 85 45 30°

steep taper ISO 7388-2

steep taper size a ±0.1 b H12 d 1 d 2 d 3 H7 d 5 -0.1 d 6 -0.05 f 1 ±0.1 f 3 l 1 ±0.2 l 6 -0.25

40 2 16,1 44,45 M16 17 69,68 63 16,6 25 65,4 22,5

50 3 25,7 69,85 M24 25 110 100 23,2 35 101,8 35,3

standard for steep tapers in accordance with DIN 2080 and corresponding pull studs

pull stud Ott-ring groove tool chuck compliant with DIN 2080

on spindle nose DIN 2079

only in conjunction with stones type C

L1

L1 115 + 0,15 L1 a k

-

l2 15° 82 13,3

l3 7 + 0,1

0,3 x 45° 0,3 x 45° d1

8°17’50’’

d4

39,6 a10

d9 d7 d2 d3 d2 d7

Ø 25,3 Ø 21,1 32 h11

Ø Ø

R 0,5

Ott-ring groove pull stud

design steep taper size d 2 d 3 g6 d 7 d 9 l 2 l 3

Ott-ring groove 40 M16 17 21,1 25 53,1 25

tool chuck DIN 2080

steep taper ±0.2 H12 d 2 a10 -0.1 ±0.15 l 7 max.

size a b d 1 d 7 d 4 k l 1

30 1,6 16,1 31,75 17,4 50 M12 8 68,4 16,2

40 1,6 16,1 44,45 25,3 63 M16 10 93,4 22,5

50 3,2 25,7 69,85 39,6 97,5 M24 12 126,8 35,3

all dimensions in mm

ATORN precision collet chucks

maximum concentricity for optimum surface quality and maximum tool life

total concentricity on ATORN precision collet chuck 3 µm (fi g. 1)

high-gloss polished surface

precision collet chuck without clamp bridge

collet chuck sits completely in the inner taper of the collet chuck (tolerance in μ range) (Figure 2)

collet chuck and clamping nut with a 30° trapezoidal thread ① and two cylindrical guides form a

single unit ②.

3 x D

fi g. 1

all of these innovations have led to the following advantages compared with other systems:

more uniform engagement of all cutting edges

longer tool life

1

2 optimised surface

fewer chatter marks

minimised vibration

higher cutting data

system concentricity ≤ 3 μm

fi g. 2

with Fahrrion 2 µm HP collet chuck

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 550

0714_EN_2018_KERN[21849874]-q.indd 716 12/17/2018 3:34:11 PM