Page 555 - Icon Ridge Presents ATORN

P. 555

Tool clamp \ Technical introduction – tool chucks

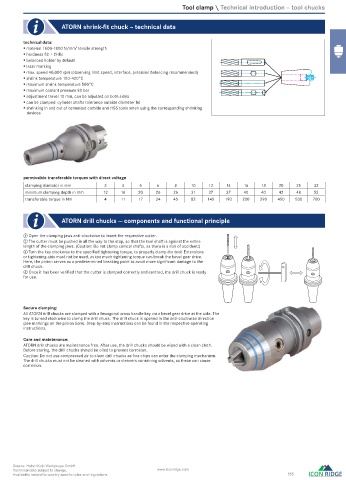

ATORN shrink-fi t chuck – technical data

technical data:

material 1600-1800 N/mm tensile strength

2

hardness 52 + 2HRc

balanced holder by default

laser marking

max. speed 40,000 rpm (observing limit speed, interface, precision balancing recommended!)

shrink temperature 100-420°C

maximum shrink temperature 500°C

maximum coolant pressure 80 bar

adjustment travel 10 mm, can be adjusted on both sides

can be clamped: cylinder sha s tolerance outside diameter h6

shrinking in and out of cemented carbide and HSS tools when using the corresponding shrinking

devices

permissible transferable torques with direct voltage

clamping diameter in mm 3 4 5 6 8 10 12 14 16 18 20 25 32

minimum clamping depth in mm 12 16 20 26 26 31 37 37 40 40 42 48 52

transferable torque in Nm 4 11 17 24 45 82 145 190 200 290 450 530 700

ATORN drill chucks — components and functional principle

① Open the clamping jaws anti-clockwise to insert the respective cutter.

② The cutter must be pushed in all the way to the stop, so that the tool sha is against the entire

length of the clamping jaws. (Caution: Do not clamp conical sha s, as there is a risk of accident!)

③ Turn the key clockwise to the specifi ed tightening torque, to properly clamp the tool. Extensions

or tightening aids must not be used, as too much tightening torque can break the bevel gear drive.

Here, the pinion serves as a predetermined breaking point to avoid more signifi cant damage to the

drill chuck.

④ Once it has been verifi ed that the cutter is clamped correctly and centred, the drill chuck is ready

for use.

Secure clamping:

All ATORN drill chucks are clamped with a hexagonal cross handle key via a bevel gear drive at the side. The

key is turned clockwise to clamp the drill chuck. The drill chuck is opened in the anti-clockwise direction

(see markings on the pinion bore). Step-by-step instructions can be found in the respective operating

instructions.

Care and maintenance:

ATORN drill chucks are maintenance free. A er use, the drill chucks should be wiped with a clean cloth.

Before storing, the drill chucks should be oiled to prevent corrosion.

Caution: Do not use compressed air to clean drill chucks as fi ne chips can enter the clamping mechanism.

The drill chucks must not be cleaned with solvents or cleaners containing solvents, as these can cause

corrosion.

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 555

0721_EN_2018_KERN[21849883]-m.indd 721 12/17/2018 3:33:59 PM