Page 557 - Icon Ridge Presents ATORN

P. 557

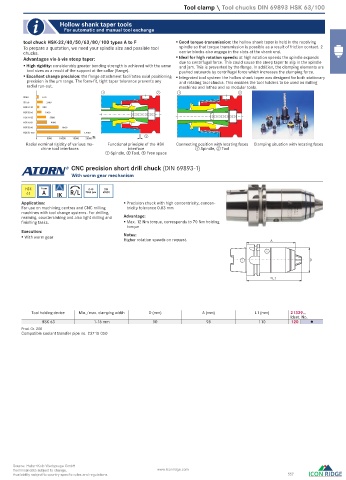

Tool clamp \ Tool chucks DIN 69893 HSK 63/100

Hollow shank taper tools

For automatic and manual tool exchange

tool chuck HSK-32/40/50/63/80/100 types A to F Good torque transmission: the hollow shank taper is held in the receiving

To prepare a quotation, we need your spindle size and possible tool spindle so that torque transmission is possible as a result of friction contact. 2

chucks. carrier blocks also engage in the slots at the shank end.

Advantages vis-à-vis steep taper: Ideal for high rotation speeds: at high rotation speeds the spindle expands

High rigidity: considerably greater bending strength is achieved with the same due to centrifugal force. This could cause the steep taper to slip in the spindle

and jam. This is prevented by the fl ange. In addition, the clamping elements are

tool sizes as a result of the support at the collar (fl ange). pushed outwards by centrifugal force which increases the clamping force.

Excellent change precision: the fl ange attachment facilitates axial positioning Integrated tool system: the hollow shank taper was designed for both stationary

precision in the µm range. The form-fi t, tight taper tolerance prevents any and rotating tool chucks. This enables the tool holders to be used on milling

radial run-out. machines and lathes and as modular tools.

1 2 1 2

3

Radial nominal rigidity of various ma- Functional principle of the HSK Connecting position with locating faces Clamping situation with locating faces

chine tool interfaces interface ① Spindle, ② Tool

① Spindle, ② Tool, ③ Free space

CNC precision short drill chuck ( DIN 69893-1 )

With worm gear mechanism

HSK Form G 40 DIN

63 A IK R/L 7000 rpm 69893

Application: Precision chuck with high concentricity, concen-

For use on machining centres and CNC milling tricity tolerance 0.03 mm

machines with tool change systems. For drilling,

reaming, countersinking and also light milling and Advantage:

fi nishing tasks. Max. 12 Nm torque, corresponds to 70 Nm holding

torque

Execution:

With worm gear Notes:

Higher rotation speeds on request. A

D

~ ~ L1

Tool holding device Min./max. clamping width D (mm) A (mm) L1 (mm) 21329...

Ident. No.

HSK 63 1-16 mm 50 98 110 120

Prod. Gr. 208

Compatible coolant transfer pipe no. 23715 050

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 557

0723_EN_2018_KERN[21849886]-o.indd 723 12/17/2018 3:34:03 PM