Page 554 - Icon Ridge Presents ATORN

P. 554

Tool clamp \ Technical introduction – tool chucks

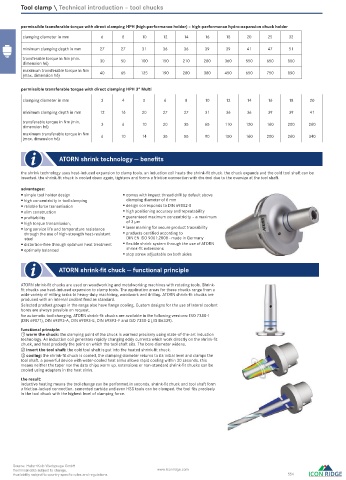

permissible transferable torque with direct clamping HPH (high-performance holder) – high-performance hydro-expansion chuck holder

clamping diameter in mm 6 8 10 12 14 16 18 20 25 32

minimum clamping depth in mm 27 27 31 36 36 39 39 41 47 51

transferable torque in Nm (min. 30 50 100 150 210 280 360 550 650 800

dimension h6)

maximum transferable torque in Nm 40 65 135 190 280 380 450 650 750 890

(max. dimension h6)

permissible transferable torque with direct clamping HPH 3° Multi

clamping diameter in mm 3 4 5 6 8 10 12 14 16 18 20

minimum clamping depth in mm 12 16 20 27 27 31 36 36 39 39 41

transferable torque in Nm (min. 3 6 10 20 35 65 110 120 160 200 260

dimension h6)

maximum transferable torque in Nm 6 10 14 35 55 90 150 160 200 260 340

(max. dimension h6)

ATORN shrink technology — benefi ts

the shrink technology uses heat-induced expansion to clamp tools. an induction coil heats the shrink-fi t chuck. the chuck expands and the cold tool sha can be

inserted. the shrink-fi t chuck is cooled down again, tightens and forms a friction connection with the tool due to the oversize at the tool sha .

advantages:

simple tool holder design comes with impact thread drill by default above

high concentricity in tool clamping clamping diameter of 6 mm

reliable force transmission design corresponds to DIN 69882-8

slim construction high positioning accuracy and repeatability

profi tability guaranteed maximum concentricity – a maximum

high torque transmission, of 3 m

long service life and temperature resistance laser marking for secure product traceability

through the use of high-strength heat-resistant products certifi ed according to

steel DIN EN ISO 9001:2008 - made in Germany

distortion-free through optimum heat treatment fl exible shrink system through the use of ATORN

optimally balanced shrink-fi t extensions

stop screw adjustable on both sides

ATORN shrink-fi t chuck — functional principle

ATORN shrink-fi t chucks are used on woodworking and metalworking machines with rotating tools. Shrink-

fi t chucks use heat-induced expansion to clamp tools. The application areas for these chucks range from a

wide variety of milling tasks to heavy-duty machining, woodwork and drilling. ATORN shrink-fi t chucks are

produced with an internal coolant feed as standard.

Selected product groups in the range also have fl ange cooling. Custom designs for the use of lateral coolant

bores are always possible on request.

for automatic tool changing, ATORN shrink-fi t chucks are available in the following versions: ISO 7388-1

(DIN 69871), DIN 69893-A, DIN 69893-E, DIN 69893-F and ISO 7388-2 (JIS B6339).

functional principle:

① warm the chuck: the clamping point of the chuck is warmed precisely using state-of-the-art induction

technology. An induction coil generates rapidly changing eddy currents which work directly on the shrink-fi t

chuck, and heat precisely the point on which the tool sha sits. The bore diameter widens.

② insert the tool sha : the cold tool sha is put into the heated shrink-fi t chuck.

③ cooling: the shrink-fi t chuck is cooled, the clamping diameter returns to its initial level and clamps the

tool sha . a powerful device with water-cooled heat sinks allows rapid cooling within 30 seconds. this

means neither the taper nor the data chips warm up. extensions or non-standard shrink-fi t chucks can be

cooled using adapters in the heat sinks.

the result:

inductive heating means the tool change can be performed in seconds. shrink-fi t chuck and tool sha form

a friction-locked connection. cemented carbide and even HSS tools can be clamped. the tool fi ts precisely

in the tool chuck with the highest level of clamping force.

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 554

0718_EN_2018_KERN[21849879]-r.indd 720 12/17/2018 3:34:10 PM