Page 558 - Icon Ridge Presents ATORN

P. 558

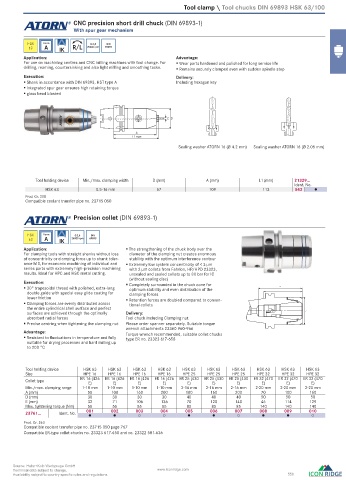

Tool clamp \ Tool chucks DIN 69893 HSK 63/100

CNC precision short drill chuck ( DIN 69893-1 )

With spur gear mechanism

HSK Form G 6,3 DIN

63 A IK R/ L 25000 rpm 69893

Application: Advantage:

For use on machining centres and CNC milling machines with tool change. For Wear parts hardened and polished for long service life

drilling, reaming, countersinking and also light milling and smoothing tasks. Remains securely clamped even with sudden spindle stop

Execution: Delivery:

Shank in accordance with DIN 69893, HST type A Including hexagon key

Integrated spur gear ensures high retaining torque

glass bead blasted

C D

A

L1 max

Sealing washer ATORN 16 (Ø 4.2 mm) Sealing washer ATORN 16 (Ø 2.05 mm)

Tool holding device Min./max. clamping width D (mm) A (mm) L1 (mm) 21329...

Ident. No.

HSK 63 0.5-16 mm 57 109 113 542

Prod. Gr. 208

Compatible coolant transfer pipe no. 23715 050

Precision collet ( DIN 69893-1 )

HSK Form G 2,5 DIN

63 A IK 25000 rpm 69893

Application: The strengthening of the chuck body over the

For clamping tools with straight shanks without loss diameter of the clamping nut creates enormous

of concentricity or clamping force up to shank toler- stability with the optimum interference contour

ance h10, for economic machining of individual and Extremely low system concentricity of < 3 µm

series parts with extremely high-precision machining with 2 µm collets from Fahrion, HP/HPD 23323,

results. Ideal for HPC and HSC metal cutting. unsealed and sealed collets up to 80 bar for IC

(without sealing disc)

Execution: Completely surrounded in the chuck cone for

30° trapezoidal thread with polished, extra-long optimum stability and even distribution of the E A

double guide with special easy glide coating for clamping forces

lower friction Retention forces are doubled compared to conven-

Clamping forces are evenly distributed across tional collets

the entire cylindrical shell surface and perfect

surfaces are achieved through the optimally Delivery: D

absorbed radial forces Tool chuck including Clamping nut

Precise centring when tightening the clamping nut Please order spanner separately. Suitable torque

Advantage: wrench attachments 23360 960-966

Torque wrench recommended, suitable collet chucks

Resistant to fl uctuations in temperature and fully type ER no. 23323 617-658

suitable for drying processes and hard milling up

to 200 °C

Tool holding device HSK 63 HSK 63 HSK 63 HSK 63 HSK 63 HSK 63 HSK 63 HSK 63 HSK 63 HSK 63

Size HPE 16 HPE 16 HPE 16 HPE 16 HPE 25 HPE 25 HPE 25 HPE 32 HPE 32 HPE 32

Collet type ER 16 (426 ER 16 (426 ER 16 (426 ER 16 (426 ER 25 (430 ER 25 (430 ER 25 (430 ER 32 (470 ER 32 (470 ER 32 (470

E)

E)

E)

E)

E)

E)

E)

E)

E)

E)

Min./max. clamping range 1-10 mm 1-10 mm 1-10 mm 1-10 mm 2-16 mm 2-16 mm 2-16 mm 2-20 mm 2-20 mm 2-20 mm

A (mm) 55 100 160 200 100 160 200 70 100 160

D (mm) 30 30 30 30 40 40 40 50 50 50

E (mm) 32 71 106 136 70 128 148 46 114 129

Max. tightening torque (Nm) 55 55 55 55 85 85 85 140 140 140

23761... Ident. No. 001 002 003 004 005 006 007 008 009 010

○

○

○

○

Prod. Gr. 263

Compatible coolant transfer pipe no. 23715 050 page 767

Compatible ER-type collet chucks no. 23323 617-658 and no. 23322 501-636

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 558

0727_EN_2018_KERN[21849893]-m.indd 727 12/17/2018 3:34:07 PM