Page 592 - Icon Ridge Presents ATORN

P. 592

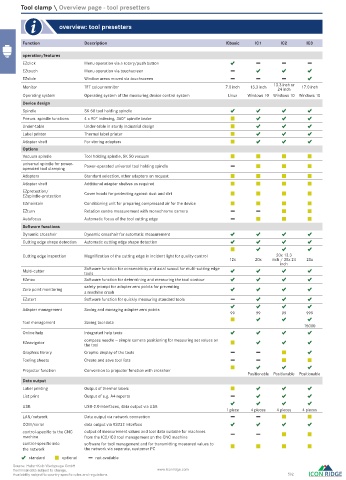

Tool clamp \ Overview page - tool presetters

overview: tool presetters

Function Description ICbasic IC1 IC2 IC3

operation/features

EZclick Menu operation via a rotary/push button

EZtouch Menu operation via touchscreen

EZslide Window areas moved via touchscreen

Monitor TFT colour monitor 7.0 inch 13.3 inch 13.3 inch or 17.0 inch

24 inch

Operating system Operating system of the measuring device control system Linux Windows 10 Windows 10 Windows 10

Device design

Spindle SK 50 tool holding spindle

Pneum. spindle functions 4 x 90° indexing, 360° spindle brake

Under-table Under-table in sturdy industrial design

Label printer Thermal label printer

Adapter shelf For storing adapters

Options

Vacuum spindle Tool holding spindle, SK 50 vacuum

universal spindle for power- Power-operated universal tool holding spindle

operated tool clamping

Adapters Standard selection, other adapters on request

Adapter shelf Additional adapter shelves as required

EZprotection/ Cover hoods for protecting against dust and dirt

EZspindle-protection

EZmaintain Conditioning unit for preparing compressed air for the device

EZturn Rotation centre measurement with monochrome camera

Autofocus Automatic focus of the tool cutting edge

So ware functions

Dynamic crosshair Dynamic crosshair for automatic measurement

Cutting edge shape detection Automatic cutting edge shape detection

Cutting edge inspection Magnifi cation of the cutting edge in incident light for quality control 20x 13.3

12x 20x inch / 38x 24 28x

inch

So ware function for concentricity and axial runout for multi-cutting edge

Multi-cutter

tools

EZmax So ware function for determining and measuring the tool contour

safety prompt for adapter zero points for preventing

Zero point monitoring

a machine crash

EZstart So ware function for quickly measuring standard tools

Adapter management Saving and managing adapter zero points

99 99 99 999

Tool management Saving tool data

15000

Online help Integrated help texts

EZnavigator compass needle — simple camera positioning for measuring set values on

the tool

Graphics library Graphic display of the tools

Tooling sheets Create and save tool lists

Projector function Conversion to projector function with crosshair

Positionable Positionable Positionable

Data output

Label printing Output of thermal labels

List print Output of e.g. A4 reports

USB USB-2.0 interfaces, data output via USB

1 piece 4 pieces 4 pieces 4 pieces

LAN/network Data output via network connection

COM/serial data output via RS232 interface

control-specifi c to the CNC output of measurement values and tool data suitable for machines

machine from the IC2/IC3 tool management on the CNC machine

control-specifi c into so ware for tool management and for transmitting measured values to

the network the network via separate, customer PC

standard optional not available

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 592

0818_EN_2018_KERN[21850023]-w.indd 818 12/17/2018 3:33:59 PM