Page 601 - Icon Ridge Presents ATORN

P. 601

Workpiece clamping \ Technical introduction – magnetic clamping technology

Magnetic clamping plates and accessories

The magnetic clamping range includes permanent-magnetic, electro-per-

manent magnetic and electro-magnetic systems, exclusively for clamping

ferromagnetic materials. Magnetic clamp types:

Advantages of the magnetic clamping technology over other clam- To satisfy diff erent requirements, clamping plates with diff erent magnetic sys-

tems are available:

ping techniques: Permanent magnetic clamping plates

Shorter setup and clamping times: Generation of magnetic force via permanent magnets

Workpieces can be easily and accurately aligned “Low magnetic fi eld; regulation of holding force possible”

Clamping plates can be switched on/off quickly and easily, as can the round Mechanical, manual on/off switching

chuck

Simultaneously clamp and machine several workpieces Electro-permanent magnetic clamping plates

Generation of magnetic force via permanent magnets with excitation winding

Workpieces are accessible from diff erent sides with a single clamping Electric on/off switching with current pulse. Control unit is required.

operation Regulation of holding force, de-magnetisation and machine release

Increase in accuracy and surface quality: Maximum precision as no mechanical movement or heat development

The workpiece is supported across the full contact surface Electromagnetic clamping plates

Distortion-free clamping “Generation of magnetic clamping force via excitation windings; high

Workpieces become plane and parallel magnetic fi eld”

No vibration during machining Electric on/off switching with current supply Control unit is required

Longer tool service life, as no vibration produced Regulation of holding force, de-magnetisation and machine release

Permanent magnetic

Permanent magnet Sine bar used on a round chuck for use on

clamping plate on a grinding machine lathes

grinding machine

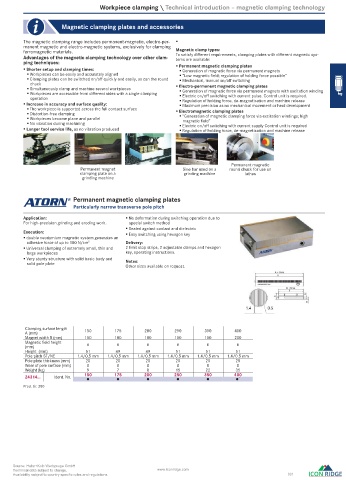

Permanent magnetic clamping plates

Particularly narrow transverse pole pitch

Application: No deformation during switching operation due to

For high-precision grinding and eroding work. special switch method

Sealed against coolant and dielectric

Execution: Easy switching using hexagon key

double neodymium magnetic system generates an

adhesive force of up to 100 N/cm 2 Delivery:

Universal clamping of extremely small, thin and 2 limit stop strips, 2 adjustable clamps and hexagon

large workpieces key, operating instructions.

Very sturdy structure with solid basic body and Notes:

solid pole plate

Other sizes available on request.

Clamping surface length

A (mm) 150 175 200 250 350 400

Magnet width B (mm) 150 100 100 150 150 200

Magnetic fi eld height 6 6 6 6 6 6

(mm)

Height (mm) 51 49 49 51 51 51

Pole pitch ST/NE 1.4/0.5 mm 1.4/0.5 mm 1.4/0.5 mm 1.4/0.5 mm 1.4/0.5 mm 1.4/0.5 mm

Pole plate thickness (mm) 20 20 20 20 20 20

Wear of pole surface (mm) 8 8 8 8 8 8

Weight (kg) 9 7 8 15 22 35

24314... Ident. No. 150 175 200 250 350 400

+

Prod. Gr. 280

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 601

0878_EN_2018_KERN[21850112]-r.indd 879 12/17/2018 3:34:19 PM