Page 603 - Icon Ridge Presents ATORN

P. 603

Workpiece clamping \ Technical introduction – vacuum clamping technology

Component-free clamping

Innovative ATORN vacuum clamping technology

where setup time and dependability are key considerations

the vacuum clamping system is particularly suitable for reliably clamping fl at, level-bottomed

workpieces to be gently clamped and machined with minimised setup times.

we off er innovative and sophisticated solutions in this regard with plenty of accessories - for opti-

mal and individual clamping.

when it comes to precision and the need to machine workpieces made of aluminium, non-ferrous

metals, graphite, plastic, glass, wood, ceramics, titanium and steel, ATORN clamping plate sets

provide an excellent working basis. these allow you to clamp your workpieces precisely and fi rmly,

facilitating excellent working results in milling or drilling applications.

vacuum systems grip the workpiece by suction and provide an excellent hold. application of a

Venturi nozzle or vacuum pump is tried and tested.

why you can achieve more with ATORN vacuum clamping technology

one set, two possibilities. this is what distinguishes the new ATORN vacuum clamping system.

the Venturi principle provides an economical option for getting started with vacuum clamping technology for short-term use. the vacuum is created through direct

connection to the compressed air supply without vacuum unit. for energy-saving continuous use in series production, a vacuum unit is recommended.

clamping can be achieved indirectly by means of sandwich adapter mats or directly on a grid plate. the use of adapter mats off ers two major advantages:

production of openings when machining workpieces

signifi cant reduction of re-clamping times as no sealing cords are required compared to direct grid plate support

application:

holds workpieces during milling, turning, grinding, polishing, drilling, reaming, countersinking, engraving, eroding, testing, measuring and coating.

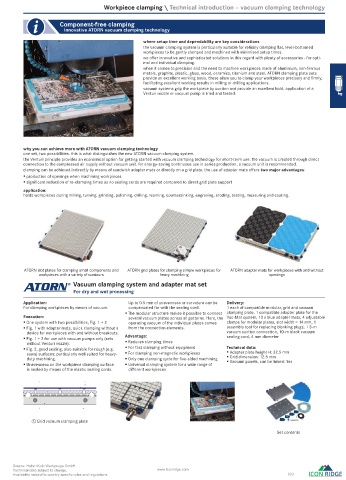

ATORN slot plates for clamping small components and ATORN grid plates for clamping simple workpieces for ATORN adapter mats for workpieces with and without

workpieces with a variety of contours heavy machining openings

Vacuum clamping system and adapter mat set

For dry and wet processing

Application: Up to 0.5 mm of unevenness or curvature can be Delivery:

For clamping workpieces by means of vacuum. compensated for with the sealing cord. 1 each of compatible modular, grid and vacuum

The modular structure makes it possible to connect clamping plate, 1 compatible adapter plate for the

Execution: several vacuum plates across all patterns. Here, the Vac-Mat system, 10 x blue adapter mats, 4 adjustable

One system with two possibilities, Fig. 1 + 2 operating vacuum of the individual plates comes clamps for modular plates, slot width = 14 mm, 1

Fig. 1 with adapter mats, quick clamping without a from the connection elements. assembly tool for replacing blanking plugs, 1 3-m

device for workpieces with and without breakouts. vacuum suction connection, 10-m black vacuum

Fig. 1 + 2 for use with vacuum pumps only (sets Advantage: sealing cord, 4 mm diameter

without Venturi nozzle). Reduces clamping times

Fig. 2, good sealing, also suitable for rough (e.g. For fast clamping without equipment Technical data:

sawn) surfaces; particularly well suited for heavy- For clamping non-magnetic workpieces Adapter plate height H: 32.5 mm

duty machining. Only one clamping cycle for fi ve-sided machining Grid dimension: 12.5 mm

Vacuum panels, can be linked: Yes

Unevenness on the workpiece clamping surface Universal clamping system for a wide range of

is sealed by means of the elastic sealing cords. diff erent workpieces

1 2

3 4

① Grid vacuum clamping plate

Set contents

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 603

0885_EN_2018_KERN[21850124]-v.indd 885 12/17/2018 3:34:20 PM