Page 605 - Icon Ridge Presents ATORN

P. 605

Workpiece clamping \ Vacuum clamping technology

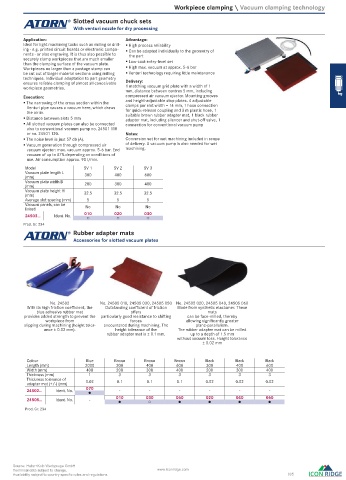

Slotted vacuum chuck sets

With venturi nozzle for dry processing

Application: Advantage:

Ideal for light machining tasks such as milling or drill- High process reliability

ing - e.g. printed circuit boards or electronic compo- Can be adapted individually to the geometry of

nents - or also engraving. It is thus also possible to the part

securely clamp workpieces that are much smaller Low-cost entry-level set

than the clamping surface of the vacuum plate.

Workpieces no larger than a postage stamp can High max. vacuum at approx. 5-6 bar

be cut out of larger material sections using milling Venturi technology requiring little maintenance

techniques. Individual adaptation to part geometry Delivery:

ensures reliable clamping of almost all conceivable

workpiece geometries. 1 matching vacuum grid plate with a width of 1

mm, distance between centres 5 mm, including

Execution: compressed air vacuum ejector. Mounting grooves

The narrowing of the cross section within the and height-adjustable stop plates. 4 adjustable

clamps per slot width = 14 mm, 1 hose connection

Venturi pipe causes a vacuum here, which draws for quick-release coupling and 3 m plastic hose, 1

the air in. suitable brown rubber adapter mat, 1 black rubber

Distance between slots 5 mm adapter mat, including silencer and shut-off valve, 1

All slotted vacuum plates can also be connected connection for conventional vacuum pump

also to conventional vacuum pump no. 24501 110

or no. 24501 120. Notes:

The noise level is just 57 db (A). Conversion set for wet machining included in scope

Vacuum generation through compressed air of delivery. A vacuum pump is also needed for wet

vacuum ejector: max. vacuum approx. 5-6 bar. End machining.

vacuum of up to 87% depending on conditions of

use. Air consumption approx. 90 l/min.

Model SV 1 SV 2 SV 3

Vacuum plate length L

(mm) 300 400 600

Vacuum plate width B

(mm) 200 300 400

Vacuum plate height H

(mm) 32.5 32.5 32.5

Average slot spacing (mm) 5 5 5

Vacuum panels, can be

linked No No No

24503... Ident. No. 010 020 030

○

○

○

Prod. Gr. 234

Rubber adapter mats

Accessories for slotted vacuum plates

No. 24502 No. 24505 010, 24505 030, 24505 050 No. 24505 020, 24505 040, 24505 060

With its high friction coeffi cient, the Outstanding coeffi cient of friction Made from synthetic elastomer. These

blue adhesive rubber mat off ers mats

provides added strength to prevent the particularly good resistance to shi ing can be face-milled, thereby

workpiece from forces allowing signifi cantly greater

slipping during machining (height toler- encountered during machining. The plane-parallelism.

ance ± 0.02 mm). height tolerance of the The rubber adapter mat can be milled

rubber adapter mat is ± 0.1 mm. up to a depth of 1.5 mm

without vacuum loss. Height tolerance

± 0.02 mm

Colour Blue Brown Brown Brown Black Black Black

Length (mm) 2000 300 400 600 300 400 600

Width (mm) 400 200 300 400 200 300 400

Thickness (mm) 1 3 3 3 3 3 3

Thickness tolerance of

adapter mat (+/-) (mm) 0.02 0.1 0.1 0.1 0.02 0.02 0.02

24502... Ident. No. 070 - - - - - -

24505... Ident. No. - 010 030 050 020 040 060

○

Prod. Gr. 234

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 605

0887_EN_2018_KERN[21850127]-s.indd 887 12/17/2018 3:34:16 PM