Page 81 - Icon Ridge Presents ATORN

P. 81

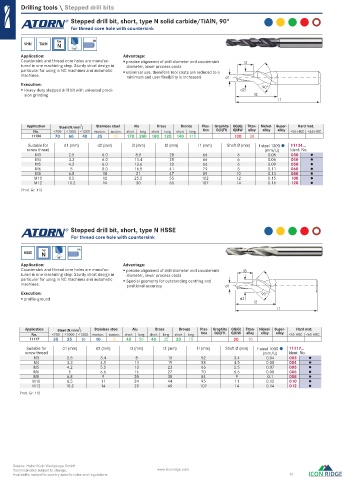

Drilling tools \ Stepped drill bits

Stepped drill bit, short, type N solid carbide/TiAlN, 90°

for thread core hole with countersink

Typ HA

VHM TiAlN N

140°

Application: Advantage:

Countersink and thread core holes are manufac- precise alignment of drill diameter and countersink l3

tured in one machining step. Sturdy short design in diameter, lower process costs

particular for using in NC machines and automatic universal use, therefore tool costs are reduced to a

machines. minimum and user fl exibility is increased d1

Execution: 90°

Heavy-duty stepped drill bit with universal preci- d2

sion grinding l2

l1

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11134 70 60 40 35 25 170 200 180 120 140 110 100 30

Suitable for d1 (mm) d2 (mm) l3 (mm) l2 (mm) l1 (mm) Sha Ø (mm) f steel 1300 11134...

screw thread (mm/U) Ident. No.

M3 2.5 6.0 8.8 28 66 6 0.05 030

M4 3.3 6.0 11.4 28 66 6 0.06 040

M5 4.2 6.0 13.6 28 66 6 0.09 050

M6 5 8.0 16.5 41 79 8 0.11 060

M8 6.8 10 21 47 89 10 0.14 080

M10 8.5 12 25.5 55 102 12 0.15 100

M12 10.2 14 30 60 107 14 0.16 120

Prod. Gr. 113

Stepped drill bit, short, type N HSSE

For thread core hole with countersink

Typ HA

HSSE N

118°

Application: Advantage:

Countersink and thread core holes are manufac- precise alignment of drill diameter and countersink l3

tured in one machining step. Sturdy short design in diameter, lower process costs

particular for using in NC machines and automatic Special geometry for outstanding centring and

machines. positional accuracy d1

Execution: 90°

profi le-ground d2

l2

l1

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11117 35 25 10 10 8 40 50 40 35 20 15 20 10

Suitable for d1 (mm) d2 (mm) l3 (mm) l2 (mm) l1 (mm) Sha Ø (mm) f steel 1000 11117...

screw thread (mm/U) Ident. No.

M3 2.5 3.4 8 15 52 3.4 0.04 003

M4 3.3 4.5 11 19 58 4.5 0.05 004

M5 4.2 5.5 13 23 66 5.5 0.07 005

M6 5 6.6 16 27 70 6.6 0.08 006

M8 6.8 9 20 35 84 9 0.1 008

M10 8.5 11 24 44 95 11 0.12 010

M12 10.2 14 29 49 107 14 0.14 012

Prod. Gr. 112

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 81

0091_EN_2018_KERN[21841807]-i.indd 92 12/17/2018 3:31:05 PM