Page 83 - Icon Ridge Presents ATORN

P. 83

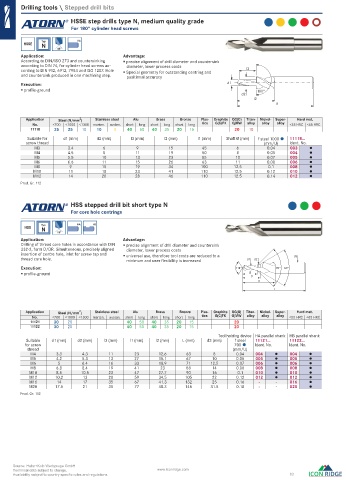

Drilling tools \ Stepped drill bits

HSSE step drills type N, medium quality grade

For 180° cylinder head screws

Typ HA

HSSE N

118°

Application: Advantage:

According to DIN/ISO 273 and countersinking precise alignment of drill diameter and countersink

according to DIN 74, for cylinder head screws ac- diameter, lower process costs

cording to DIN 912, 6912, 7984 and ISO 1207. Hole Special geometry for outstanding centring and l3

and countersink produced in one machining step. positional accuracy

Execution: d1

profi le-ground 180°

d2

l2

l1

Application Steel (N/mm ) 2 Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11118 35 25 10 10 8 40 50 40 35 20 15 20 10

Suitable for d1 (mm) d2 (mm) l3 (mm) l2 (mm) l1 (mm) Sha Ø (mm) f steel 1000 11118...

screw thread (mm/U) Ident. No.

M3 3.4 6 9 15 45 6 0.04 003

M4 4.5 8 11 19 50 8 0.05 004

M5 5.5 10 13 23 55 10 0.07 005

M6 6.6 11 15 26 63 11 0.08 006

M8 9 15 19 34 100 12.5 0.1 008

M10 11 18 23 41 110 12.5 0.12 010

M12 14 20 28 46 110 12.5 0.14 012

Prod. Gr. 112

HSS stepped drill bit short type N

For core hole centrings

Typ HA HB

HSS

N

118°

Application: Advantage:

Drilling of thread core holes in accordance with DIN precise alignment of drill diameter and countersink

332-2, form D/DR. Simultaneous, precisely aligned diameter, lower process costs

insertion of centre hole, inlet for screw tap and universal use, therefore tool costs are reduced to a d3

thread core hole. minimum and user fl exibility is increased d1 d2

Execution: 118° 90° 60°

profi le-ground l3

l2

l1

L

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

2

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11121 30 20 40 50 40 35 20 15 20

11122 30 20 40 50 40 35 20 15 20

Tool holding device HA parallel shank HB parallel shank

Suitable d1 (mm) d2 (mm) l3 (mm) l1 (mm) l2 (mm) L (mm) d3 (mm) f steel 11121... 11122...

for screw 700 Ident. No. Ident. No.

thread (mm/U)

M4 3.3 4.3 11 23 12.6 63 8 0.04 004 004

M5 4.2 5.3 13 27 15.1 67 10 0.05 005 005

M6 5 6.4 16 33 18.9 71 12.5 0.07 006 006

M8 6.8 8.4 19 41 23 88 14 0.08 008 008

M10 8.5 10.5 23 47 27.7 90 16 0.1 010 010

M12 10.2 13 28 59 34.5 105 22 0.12 012 012

M16 14 17 35 67 41.3 132 25 0.16 - - 016

M20 17.5 21 38 77 48.3 145 31.5 0.18 - - 020

Prod. Gr. 112

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 83

0096_EN_2018_KERN[21841814]-k.indd 96 12/17/2018 3:31:04 PM