Page 80 - Icon Ridge Presents ATORN

P. 80

Drilling tools \ Twist drill HSS/HSSE morse taper shank

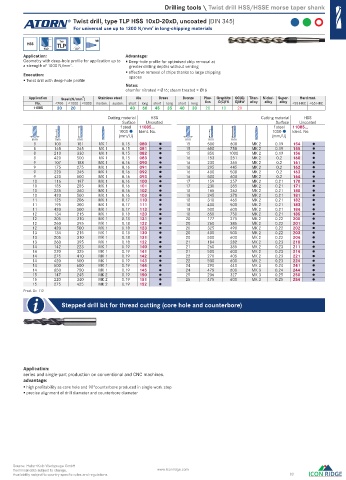

Twist drill, type TLP HSS 10xD-20xD, uncoated ( DIN 345 )

For universal use up to 1300 N/mm in long-chipping materials

2

Typ MK

HSS TLP

10xD 130°

Application: Advantage:

Geometry with deep-hole profi le for application up to Deep-hole profi le for optimised chip removal at

a strength of 1000 N/mm . 2 greater drilling depths without venting

Execution: eff ective removal of chips thanks to large chipping

spaces

Twist drill with deep-hole profi le

Notes:

chamfer nitrated < Ø16; steam treated > Ø16

2

Application Steel (N/mm ) Stainless steel Alu Brass Bronze Plas- Graphite GG(G) Titan- Nickel- Super- Hard mat.

No. <700 <1000 <1300 marten. austen. short long short long short long tics G(C)FK GjMW alloy alloy alloy <55 HRC <65 HRC

11085 30 20 40 60 45 35 40 30 20 10 20

Cutting material HSS Cutting material HSS

Surface Uncoated Surface Uncoated

f steel 11085... f steel 11085...

1000 Ident. No. 1000 Ident. No.

(mm/U) (mm/U)

mm mm mm mm mm mm

8 100 181 MK 1 0.15 080 15 500 600 MK 2 0.19 154

8 165 265 MK 1 0.15 081 15 650 750 MK 2 0.19 155

8 210 330 MK 1 0.15 082 15 850 1000 MK 2 0.19 156

8 420 500 MK 1 0.15 083 16 153 251 MK 2 0.2 160

9 107 188 MK 1 0.16 090 16 230 355 MK 2 0.2 161

9 175 275 MK 1 0.16 091 16 295 445 MK 2 0.2 162

9 220 345 MK 1 0.16 092 16 400 500 MK 2 0.2 163

9 420 500 MK 1 0.16 093 16 500 600 MK 2 0.2 164

10 116 197 MK 1 0.16 100 17 159 257 MK 2 0.21 170

10 185 285 MK 1 0.16 101 17 230 355 MK 2 0.21 171

10 235 360 MK 1 0.16 102 18 165 263 MK 2 0.21 180

10 420 500 MK 1 0.16 103 18 245 370 MK 2 0.21 181

11 125 206 MK 1 0.17 110 18 310 465 MK 2 0.21 182

11 195 300 MK 1 0.17 111 18 400 500 MK 2 0.21 183

11 420 500 MK 1 0.17 113 18 500 600 MK 2 0.21 184

12 134 215 MK 1 0.18 120 18 650 750 MK 2 0.21 185

12 205 310 MK 1 0.18 121 20 177 275 MK 2 0.22 200

12 260 395 MK 1 0.18 122 20 260 385 MK 2 0.22 201

12 420 500 MK 1 0.18 123 20 325 490 MK 2 0.22 202

13 134 215 MK 1 0.18 130 20 400 500 MK 2 0.22 203

13 205 310 MK 1 0.18 131 20 500 600 MK 2 0.22 204

13 260 395 MK 1 0.18 132 21 184 282 MK 2 0.23 210

14 142 223 MK 1 0.19 140 21 260 385 MK 2 0.23 211

14 220 325 MK 1 0.19 141 21 500 600 MK 2 0.23 214

14 275 410 MK 1 0.19 142 22 270 405 MK 2 0.23 221

14 420 500 MK 1 0.19 143 22 500 600 MK 2 0.23 224

14 500 600 MK 1 0.19 144 24 290 440 MK 3 0.24 241

14 650 750 MK 1 0.19 145 24 475 600 MK 3 0.24 244

15 147 245 MK 2 0.19 150 25 206 327 MK 3 0.25 250

15 220 340 MK 2 0.19 151 25 475 600 MK 3 0.25 254

15 275 425 MK 2 0.19 152

Prod. Gr. 112

Stepped drill bit for thread cutting (core hole and counterbore)

Application:

series and single-part production on conventional and CNC machines.

advantage:

high profi tability as core hole and 90°counterbore produced in single work step

precise alignment of drill diameter and counterbore diameter

Source: Hahn+Kolb Werkzeuge GmbH

Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations. 80

0091_EN_2018_KERN[21841807]-i.indd 91 12/17/2018 3:31:03 PM