Page 81 - Icon Ridge Sanitary-Heating-Air Catalog

P. 81

Building Services

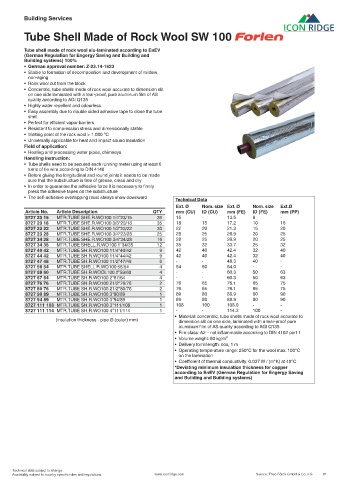

Tube Shell Made of Rock Wool SW 100

Tube shell made of rock wool alu-laminated according to EnEV

(German Regulation for Engergy Saving and Building and

Building systems) 100%

• German approval number: Z-23.14-1623

• Stable to formation of decomposition and development of mildew,

non-aging

• Rock wool cut from the block

• Concentric, tube shells made of rock wool accurate to dimension slit

on one side laminated with a tear-proof, pure aluminum film of AS

quality according to AGI Q135

• Highly water repellent and odourless

• Easy assembly due to double sided adhesive tape to close the tube

shell

• Perfect for efficient vapor barriers

• Resistant to compression stress and dimensionally stable

• Melting point of the rock wool > 1.000 °C

• Universally applicable for heat and impact sound insulation

Field of application:

• Heating and processing water pipes, chimneys

Handling instruction:

• Tube shells need to be secured each running meter using at least 6

turns of tie wire according to DIN 4140

• Before gluing the longitudinal and round joints it needs to be made

sure that the substructure is free of grease, clean and dry

• In order to guarantee the adhesive force it is necessary to firmly

press the adhesive tapes on the substructure

• The self-adhesive overlapping must always show downward

Technical Data

Ext. Ø Nom. size Ext. Ø Nom. size Ext.Ø

Article No. Article Description QTY mm (CU) ID (CU) mm (FE) ID (FE) mm (PP)

8727 23 15 MTR.TUBE SHE.R.WO100 1/4"23/15 36 15 - 13.5 8 -

8727 23 18 MTR.TUBE SHE.R.WO100 3/8"23/18 35 18 15 17.2 10 16

8727 23 22 MTR.TUBE SHE.R.WO100 1/2"23/22 30 22 20 21.3 15 20

8727 23 28 MTR.TUBE SHE.R.WO100 3/4"23/28 25 28 25 26.9 20 25

8727 34 28 MTR.TUBE SHE.R.WO100 3/4"34/28 16 28 25 26.9 20 25

8727 34 35 MTR.TUBE SHELL.R.WO100 1"34/35 12 35 32 33.7 25 32

8727 40 42 MTR.TUBE SH.R.WO100 11/4"40/42 9 42 40 42.4 32 40

8727 44 42 MTR.TUBE SH.R.WO100 11/4"44/42 9 42 40 42.4 32 40

8727 47 48 MTR.TUBE SH.R.WO100 11/2"47/48 6 - - 48.3 40 -

8727 56 54 MTR.TUBE SHELL R.WO100 56/54 4 54 50 54.0 - -

8727 59 60 MTR.TUBE SH.R.WOOL100 2"59/60 4 - - 60.3 50 63

8727 67 64 MTR.TUBE SH.R.WO100 2"67/64 4 - - 60.3 50 63

8727 76 76 MTR.TUBE SH.R.WO100 21/2"76/76 2 76 65 76.1 65 75

8727 80 76 MTR.TUBE SH.R.WO100 21/2"80/76 2 76 65 76.1 65 75

8727 90 89 MTR.TUBE SH.R.WO100 3"90/89 1 89 80 88.9 80 90

8727 94 89 MTR.TUBE SH.R.WO100 3"94/89 1 89 80 88.9 80 90

8727 111 108 MTR.TUBE SH.R.WO100 3"111/108 1 108 100 108.0 - -

8727 111 114 MTR.TUBE SH.R.WO100 4"111/114 1 - - 114.3 100 -

• Material: concentric, tube shells made of rock wool accurate to

(insulation thickness - pipe Ø (outer) mm) dimension slit on one side, laminated with a tear-proof pure

aluminum film of AS quality according to AGI Q135

• Fire class: A2 – not inflammable according to DIN 4102 part 1

• Volume weight: 80 kg/m³

• Delivery form/length: box, 1 m

• Operating temperature range: 250°C for the wool max. 100°C

on the lamination

• Coefficient of thermal conductivity: 0.037 W / (m*K) at 40°C

*Deviating minimum insulation thickness for copper

according to EnEV (German Regulation for Engergy Saving

and Building and Building systems)

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 81