Page 241 - Icon Ridge Working Gear

P. 241

Working security

An overview of FÖRCH products

All of our products have the CE mark and comply with the up-to-date valid EN standards.

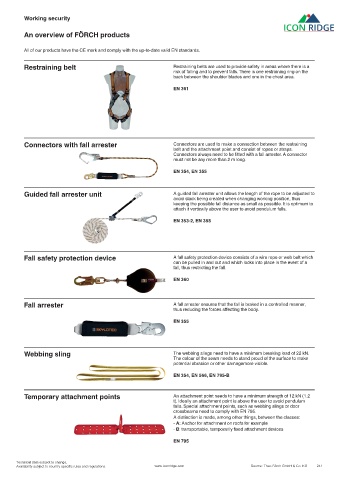

Restraining belt Restraining belts are used to provide safety in areas where there is a

risk of falling and to prevent falls. There is one restraining ring on the

back between the shoulder blades and one in the chest area.

EN 361

Connectors with fall arrester Connectors are used to make a connection between the restraining

belt and the attachment point and consist of ropes or straps.

Connectors always need to be fitted with a fall arrester. A connector

must not be any more than 2 m long.

EN 354, EN 355

Guided fall arrester unit A guided fall arrester unit allows the length of the rope to be adjusted to

avoid slack being created when changing working position, thus

keeping the possible fall distance as small as possible. It is optimum to

attach it vertically above the user to avoid pendulum falls.

EN 353-2, EN 358

Fall safety protection device A fall safety protection device consists of a wire rope or web belt which

can be pulled in and out and which locks into place in the event of a

fall, thus restricting the fall.

EN 360

Fall arrester A fall arrester ensures that the fall is braked in a controlled manner,

thus reducing the forces affecting the body.

EN 355

Webbing sling The webbing slings need to have a minimum breaking load of 22 kN.

The colour of the seam needs to stand proud of the surface to make

potential abrasion or other damagemore visible.

EN 354, EN 566, EN 795-B

Temporary attachment points An attachment point needs to have a minimum strength of 12 kN (1.2

t). Ideally an attachment point is above the user to avoid pendulum

falls. Special attachment points, such as webbing slings or door

crossbeams need to comply with EN 795.

A distinction is made, among other things, between the classes:

- A: Anchor for attachment on roofs for example

- B: transportable, temporarily fixed attachment devices

EN 795

Technical data subject to change.

Availability subject to country specific rules and regulations. www.iconridge.com Source: Theo Förch GmbH & Co. KG 241