Page 64 - Industrial Tools Catalog (2)

P. 64

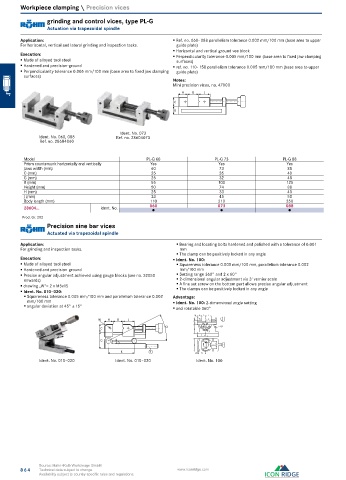

Workpiece clamping \ Precision vices

grinding and control vices, type PL-G

Actuation via trapezoidal spindle

Application: Ref. no. 060- 088 parallelism tolerance 0.002 mm/100 mm (base area to upper

For horizontal, vertical and lateral grinding and inspection tasks. guide plate)

Horizontal and vertical ground vee block

Execution: Perpendicularity tolerance 0.005 mm/100 mm (base area to fixed jaw clamping

Made of alloyed tool steel surfaces)

Hardened and precision-ground ref. no. 110- 150 parallelism tolerance 0.005 mm/100 mm (base area to upper

Perpendicularity tolerance 0.005 mm/100 mm (base area to fixed jaw clamping guide plate)

surfaces)

Notes:

Mini precision vices, no. 47000

H B J

C

G

Ident. No. 073

Ident. No. 060, 088 Ref. no. 28604073

Ref. no. 28604060

Model PL-G 60 PL-G 73 PL-G 88

Prism countersunk horizontally and vertically Yes Yes Yes

Jaws width (mm) 60 73 88

C (mm) 25 35 40

G (mm) 25 32 48

B (mm) 55 100 125

Height (mm) 50 74 88

H (mm) 25 33 40

J (mm) 33 45 50

Body length (mm) 110 210 250

28604... Ident. No. 060 073 088

●

●

●

Prod. Gr. 202

Precision sine bar vices

Actuated via trapezoidal spindle

Application: Bearing and locating bolts hardened and polished with a tolerance of 0.001

For grinding and inspection tasks. mm

The clamp can be positively locked in any angle

Execution: Ident. No. 100:

Made of alloyed tool steel Squareness tolerance 0.005 mm/100 mm, parallelism tolerance 0.002

Hardened and precision-ground mm/100 mm

Precise angular adjustment achieved using gauge blocks (see no. 32050 Setting range 360° and 2 x 60°

onwards) 2-dimensional angular adjustment via 3‘ vernier scale

drawing „W“= 2 x M5x15 A fine set screw on the bottom part allows precise angular adjustment

Ident. No. 010–020: The clamps can be positively locked in any angle

Squareness tolerance 0.005 mm/100 mm and parallelism tolerance 0.002 Advantage:

mm/100 mm Ident. No. 100: 2-dimensional angle setting

angular deviation at 45° ± 15“ and rotatable 360°

W H B J

W H B J C

G

1

C P

R T

G β

L

K 1 M N

Ident. No. 010–020 Ident. No. 010–020 Ident. No. 100

Source: Hahn+Kolb Werkzeuge GmbH

864 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.