Page 66 - Industrial Tools Catalog (2)

P. 66

Workpiece clamping \ Electronic drills vices

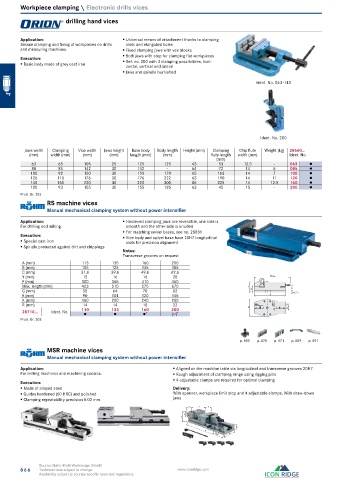

drilling hand vices

Application: Universal means of attachment thanks to clamping

Secure clamping and fixing of workpieces on drills slots and elongated holes

and measuring machines. Fixed clamping jaws with vee blocks

Execution: Both jaws with step for clamping flat workpieces

Ref. no. 200 with 3 clamping possibilities, hori-

Basic body made of grey cast iron zontal, vertical and lateral

Jaws and spindle burnished

Ident. No. 063–140

Ident. No. 200

Jaws width Clamping Vice width Jaws height Base body Body length Height (mm) Clamping Chip flute Weight (kg) 28660...

(mm) width (mm) (mm) (mm) length (mm) (mm) flute length width (mm) Ident. No.

(mm)

63 65 105 25 125 125 43 53 12.5 - 063 ●

80 85 142 30 142 - 64 72 14 5 085 ●

100 92 150 30 150 170 65 163 14 7 100 ●

120 110 176 30 176 222 63 190 14 11 120 ●

140 150 220 40 220 300 85 225 14 12.5 140 ●

100 93 155 30 155 185 63 45 15 - 200 ●

Prod. Gr. 282

RS machine vices

Manual mechanical clamping system without power intensifier

Application: Hardened clamping jaws are reversible, one side is

For drilling and milling. smooth and the other side is knurled

For matching swivel bases, see no. 28881

Execution: Vice body and swivel base have 20H7 longitudinal

Special cast iron slots for precision alignment

Spindle protected against dirt and chippings

Notes:

Transverse grooves on request

A (mm) 113 135 160 200

B (mm) 105 125 145 185

C (mm) 31.6 39.6 49.6 62.6

Y (mm) 12 16 16 20 D max

F (mm) 300 365 410 460 Y B

Max. length (mm) 423 510 575 675 E C

G (mm) 58 64 70 82 G

E (mm) 90 104 120 145 F

K (mm) 160 200 240 280

R (mm) 14 14 18 22 K M6 20H7 R

28710... Ident. No. 110 135 160 200 +

+

●

●

(○)

●

Prod. Gr. 203

p. 880 p. 870 p. 871 p. 889 p. 891

MSR machine vices

Manual mechanical clamping system without power intensifier

Application: Aligned on the machine table via longitudinal and transverse grooves 20H7

For milling machines and machining centres. Rough adjustment of clamping range using rigging pins

Execution: 4 adjustable clamps are required for optimal clamping

Made of alloyed steel Delivery:

Guides hardened (60 HRC) and polished With spanner, workpiece limit stop and 4 adjustable clamps. With draw-down

Clamping repeatability precision 0.02 mm jaws

H A B

H C

E

G

F

W K

Source: Hahn+Kolb Werkzeuge GmbH

866 Technical data subject to change. www.iconridge.com

Availability subject to country specific rules and regulations.