Page 58 - KRA Annual Report 2020

P. 58

KRA ANNUAL REPORT Company

2020 Improvement

Activities

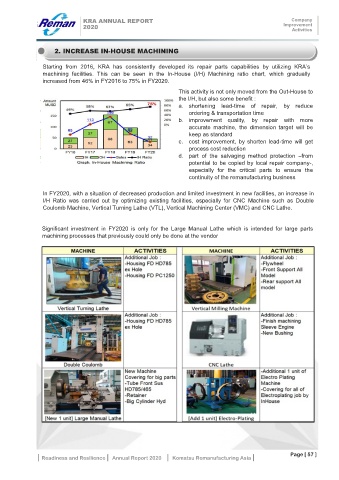

2. INCREASE IN-HOUSE MACHINING

Starting from 2016, KRA has consistently developed its repair parts capabilities by utilizing KRA’s

machining facilities. This can be seen in the In-House (I/H) Machining ratio chart, which gradually

increased from 46% in FY2016 to 75% in FY2020.

This activity is not only moved from the Out-House to

the I/H, but also some benefit :

a. shortening lead-time of repair, by reduce

ordering & transportation time

b. improvement quality, by repair with more

accurate machine, the dimension target will be

keep as standard

c. cost improvement, by shorten lead-time will get

process cost reduction

d. part of the salvaging method protection –from

potential to be copied by local repair company-,

especially for the critical parts to ensure the

continuity of the remanufacturing business

In FY2020, with a situation of decreased production and limited investment in new facilities, an increase in

I/H Ratio was carried out by optimizing existing facilities, especially for CNC Machine such as Double

Coulomb Machine, Vertical Turning Lathe (VTL), Vertical Machining Center (VMC) and CNC Lathe.

Significant investment in FY2020 is only for the Large Manual Lathe which is intended for large parts

machining processes that previously could only be done at the vendor

Page [ 57 ]

| Readiness and Resilience | Annual Report 2020 | Komatsu Remanufacturing Asia |