Page 94 - Stedall Parts Catalogue 14th Edition

P. 94

HINGES

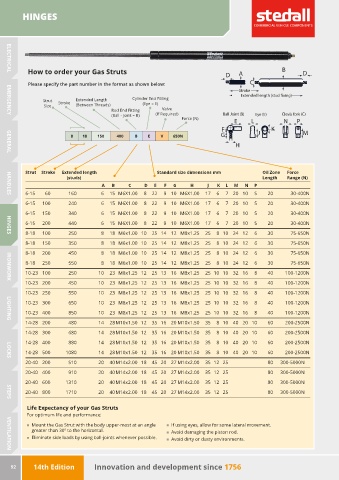

How to order your Gas Struts D A B B D

ELECTRICAL

D A D

C

Please specify the part number in the format as shown below: C

Stroke

Stroke

Extended length (stud xing)

Strut Stroke Extended Length Cylinder End Fitting Extended length (stud xing)

Size (Between Threads) (Eye = E)

Rod End Fitting Valve Ball Joint (B) Eye (E) Clevis fork (C)

(Ball - Joint = B) (If Required) Ball Joint (B) Eye (E) Clevis fork (C)

N

EMERGENCY

Force (N) E E L L N P P

F K

F J K M

G

H

8 18 150 400 B E V 650N G H J M

H

H

GENERAL

Strut Stroke Extended length Standard size dimensions mm Oil Zone Force

(studs) Length Range (N)

A B C D E F G H J K L M N P

6-15 60 160 6 15 M6X1.00 8 22 9 10 M6X1.00 17 6 7 20 10 5 20 30-400N

HANDLES

6-15 100 240 6 15 M6X1.00 8 22 9 10 M6X1.00 17 6 7 20 10 5 20 30-400N

6-15 150 340 6 15 M6X1.00 8 22 9 10 M6X1.00 17 6 7 20 10 5 20 30-400N

6-15 200 440 6 15 M6X1.00 8 22 9 10 M6X1.00 17 6 7 20 10 5 20 30-400N

8-18 100 250 8 18 M6x1.00 10 25 14 12 M8x1.25 25 8 10 24 12 6 30 75-650N

HINGES

8-18 150 350 8 18 M6x1.00 10 25 14 12 M8x1.25 25 8 10 24 12 6 30 75-650N

8-18 200 450 8 18 M6x1.00 10 25 14 12 M8x1.25 25 8 10 24 12 6 30 75-650N

8-18 250 550 8 18 M6x1.00 10 25 14 12 M8x1.25 25 8 10 24 12 6 30 75-650N

10-23 100 250 10 23 M8x1.25 12 25 13 16 M8x1.25 25 10 10 32 16 8 40 100-1200N

10-23 200 450 10 23 M8x1.25 12 25 13 16 M8x1.25 25 10 10 32 16 8 40 100-1200N

IRONWORK

10-23 250 550 10 23 M8x1.25 12 25 13 16 M8x1.25 25 10 10 32 16 8 40 100-1200N

10-23 300 650 10 23 M8x1.25 12 25 13 16 M8x1.25 25 10 10 32 16 8 40 100-1200N

10-23 400 850 10 23 M8x1.25 12 25 13 16 M8x1.25 25 10 10 32 16 8 40 100-1200N

14-28 200 480 14 28 M10x1.50 12 35 16 20 M10x1.50 35 8 10 40 20 10 60 200-2500N

LIGHTING

14-28 300 680 14 28 M10x1.50 12 35 16 20 M10x1.50 35 8 10 40 20 10 60 200-2500N

14-28 400 880 14 28 M10x1.50 12 35 16 20 M10x1.50 35 8 10 40 20 10 60 200-2500N

14-28 500 1080 14 28 M10x1.50 12 35 16 20 M10x1.50 35 8 10 40 20 10 60 200-2500N

LOCKS

20-40 200 510 20 40 M14x2.00 18 45 20 27 M14x2.00 35 12 25 80 300-5000N

20-40 400 910 20 40 M14x2.00 18 45 20 27 M14x2.00 35 12 25 80 300-5000N

20-40 600 1310 20 40 M14x2.00 18 45 20 27 M14x2.00 35 12 25 80 300-5000N

20-40 800 1710 20 40 M14x2.00 18 45 20 27 M14x2.00 35 12 25 80 300-5000N

STEPS

Life Expectancy of your Gas Struts

For optimum life and performance:

Mount the Gas Strut with the body upper-most at an angle If using eyes, allow for some lateral movement.

greater than 30º to the horizontal. Avoid damaging the piston rod.

Eliminate side loads by using ball-joints whenever possible. Avoid dirty or dusty environments.

VENTILATION

92 14th Edition Innovation and development since 1756