Page 14 - Industrial Technology EXTRA - 29th June 2020

P. 14

FASTENING AND JOINING...

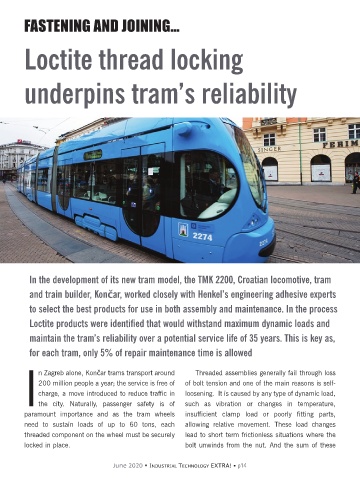

Loctite thread locking

underpins tram’s reliability

In the development of its new tram model, the TMK 2200, Croatian locomotive, tram

and train builder, Končar, worked closely with Henkel’s engineering adhesive experts

to select the best products for use in both assembly and maintenance. In the process

Loctite products were identified that would withstand maximum dynamic loads and

maintain the tram’s reliability over a potential service life of 35 years. This is key as,

for each tram, only 5% of repair maintenance time is allowed

n Zagreb alone, Končar trams transport around Threaded assemblies generally fail through loss

200 million people a year; the service is free of of bolt tension and one of the main reasons is self-

charge, a move introduced to reduce traffic in loosening. It is caused by any type of dynamic load,

Ithe city. Naturally, passenger safety is of such as vibration or changes in temperature,

paramount importance and as the tram wheels insufficient clamp load or poorly fitting parts,

need to sustain loads of up to 60 tons, each allowing relative movement. These load changes

threaded component on the wheel must be securely lead to short term frictionless situations where the

locked in place. bolt unwinds from the nut. And the sum of these

June 2020 • INDUSTRIAL TECHNOLOGY EXTRA! • p14