Page 13 - Basic PD Theory

P. 13

Partial Discharge for Stator Windings

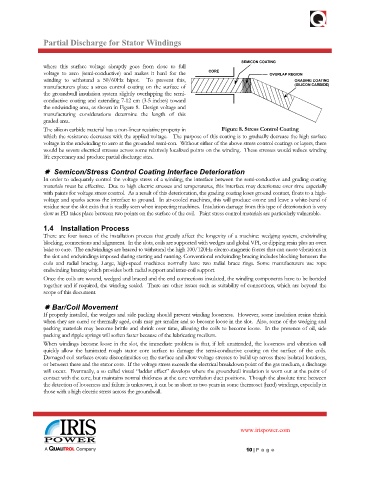

where this surface voltage abruptly goes from close to full

voltage to zero (semi-conductive) and makes it hard for the

winding to withstand a 50/60Hz hipot. To prevent this,

manufacturers place a stress control coating on the surface of

the groundwall insulation system slightly overlapping the semi-

conductive coating and extending 7-12 cm (3-5 inches) toward

the endwinding area, as shown in Figure 8. Design voltage and

manufacturing considerations determine the length of this

graded area.

The silicon carbide material has a non-linear resistive property in Figure 8. Stress Control Coating

which the resistance decreases with the applied voltage. The purpose of this coating is to gradually decrease the high surface

voltage in the endwinding to zero at the grounded semi-con. Without either of the above stress control coatings or layers, there

would be severe electrical stresses across some relatively localized points on the winding. These stresses would reduce winding

life expectancy and produce partial discharge sites.

Semicon/Stress Control Coating Interface Deterioration

In order to adequately control the voltage stress of a winding, the interface between the semi-conductive and grading coating

materials must be effective. Due to high electric stresses and temperatures, this interface may deteriorate over time especially

with paints for voltage stress control. As a result of this deterioration, the grading coating loses ground contact, floats to a high-

voltage and sparks across the interface to ground. In air-cooled machines, this will produce ozone and leave a white-band of

residue near the slot exits that is readily seen when inspecting machines. Insulation damage from this type of deterioration is very

slow as PD takes place between two points on the surface of the coil. Paint stress control materials are particularly vulnerable.

1.4 Installation Process

There are four issues of the installation process that greatly affect the longevity of a machine: wedging system, endwinding

blocking, connections and alignment. In the slots, coils are supported with wedges and global VPI, or dipping resin plus an oven

bake to cure. The endwindings are braced to withstand the high 100/120Hz electro-magnetic forces that can cause vibrations in

the slot and endwindings imposed during starting and running. Conventional endwinding bracing includes blocking between the

coils and radial bracing. Large, high-speed machines normally have two radial brace rings. Some manufacturers use rope

endwinding bracing which provides both radial support and inter-coil support.

Once the coils are wound, wedged and braced and the end connections insulated, the winding components have to be bonded

together and if required, the winding sealed. There are other issues such as suitability of connections, which are beyond the

scope of this document.

Bar/Coil Movement

If properly installed, the wedges and side packing should prevent winding looseness. However, some insulation resins shrink

when they are cured or thermally aged, coils may get smaller and so become loose in the slot. Also, some of the wedging and

packing materials may become brittle and shrink over time, allowing the coils to become loose. In the presence of oil, side

packing and ripple springs will soften faster because of the lubricating medium.

When windings become loose in the slot, the immediate problem is that, if left unattended, the looseness and vibration will

quickly allow the laminated rough stator core surface to damage the semi-conductive coating on the surface of the coils.

Damaged coil surfaces create discontinuities on the surface and allow voltage stresses to build up across these isolated locations,

or between these and the stator core. If the voltage stress exceeds the electrical breakdown point of the gas medium, a discharge

will occur. Eventually, a so called visual “ladder effect” develops where the groundwall insulation is worn out at the point of

contact with the core, but maintains normal thickness at the core ventilation duct positions. Though the absolute time between

the detection of looseness and failure is unknown, it can be as short as two years in some thermoset (hard) windings, especially in

those with a high electric stress across the groundwall.

www.irispower.com

10 | P ag e