Page 63 - Basic PD Theory

P. 63

Failure Mechanisms

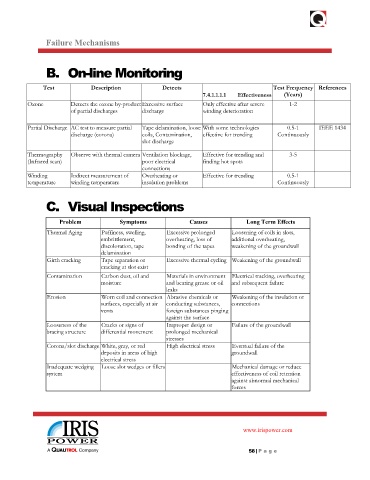

B. On-line Monitoring

Test Description Detects Test Frequency References

7.4.1.1.1.1 Effectiveness (Years)

Ozone Detects the ozone by-product Excessive surface Only effective after severe 1-2

of partial discharges discharge winding deterioration

Partial Discharge AC test to measure partial Tape delamination, loose With some technologies 0.5-1 IEEE 1434

discharge (corona) coils, Contamination, effective for trending Continuously

slot discharge

Thermography Observe with thermal camera Ventilation blockage, Effective for trending and 3-5

(Infrared scan) poor electrical finding hot spots

connections

Winding Indirect measurement of Overheating or Effective for trending 0.5-1

temperature winding temperature insulation problems Continuously

C. Visual Inspections

Problem Symptoms Causes Long Term Effects

Thermal Aging Puffiness, swelling, Excessive prolonged Loosening of coils in slots,

embrittlement, overheating, loss of additional overheating,

discoloration, tape bonding of the tapes weakening of the groundwall

delamination

Girth cracking Tape separation or Excessive thermal cycling Weakening of the groundwall

cracking at slot exist

Contamination Carbon dust, oil and Materials in environment Electrical tracking, overheating

moisture and bearing grease or oil and subsequent failure

leaks

Erosion Worn coil and connection Abrasive chemicals or Weakening of the insulation or

surfaces, especially at air conducting substances, connections

vents foreign substances pinging

against the surface

Looseness of the Cracks or signs of Improper design or Failure of the groundwall

bracing structure differential movement prolonged mechanical

stresses

Corona/slot discharge White, gray, or red High electrical stress Eventual failure of the

deposits in areas of high groundwall

electrical stress

Inadequate wedging Loose slot wedges or fillers Mechanical damage or reduce

system effectiveness of coil retention

against abnormal mechanical

forces

www.irispower.com

58 | P ag e