Page 20 - february

P. 20

METALWORKING EQUIPMENT AND TOOLS

CORRECT SELECTION OF THE LINEAR GUIDE

IMPORTANCE OF PRE-LOAD AND FRICTION

Some engineers often neglect important parameters of linear guides and carriages (traversing

units) in the design and manufacture of equipment. In addition to the accuracy class, load-

carrying capacity and modern technological innovations, such as the maintenance-free block

type, the system linear displacement there are a number of important characteristics that must

be considered in the design process.

PURPOSE OF PRE-TENSION

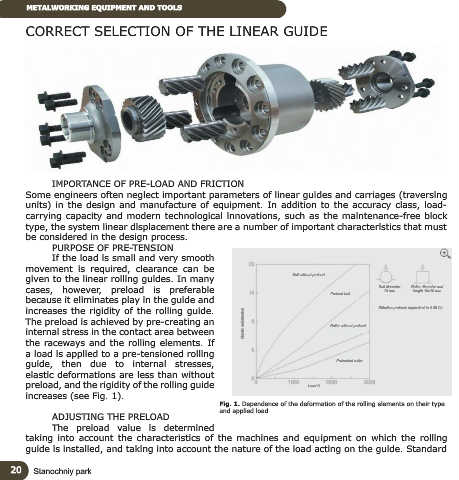

If the load is small and very smooth

movement is required, clearance can be

given to the linear rolling guides. In many Ball without preload

cases, however, preload is preferable Preload ball Ball diameter Roller diameter and

10 mm

length 10x10 mm

because it eliminates play in the guide and

increases the rigidity of the rolling guide. Effective preload: equivalent to 0.05 Co

The preload is achieved by pre-creating an Elastic deformation Roller without preload

internal stress in the contact area between

the raceways and the rolling elements. If

a load is applied to a pre-tensioned rolling

guide, then due to internal stresses, Preloaded roller

elastic deformations are less than without

preload, and the rigidity of the rolling guide Load N

increases (see Fig. 1).

Fig. 1. Dependence of the deformation of the rolling elements on their type

and applied load

ADJUSTING THE PRELOAD

The preload value is determined

taking into account the characteristics of the machines and equipment on which the rolling

guide is installed, and taking into account the nature of the load acting on the guide. Standard

20 Stanochniy park