Page 25 - february

P. 25

METALWORKING EQUIPMENT AND TOOLS

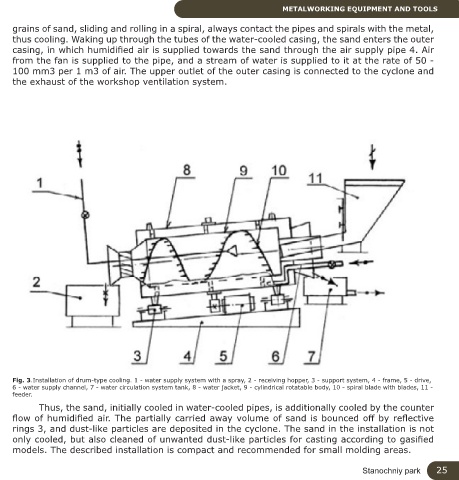

grains of sand, sliding and rolling in a spiral, always contact the pipes and spirals with the metal,

thus cooling. Waking up through the tubes of the water-cooled casing, the sand enters the outer

casing, in which humidified air is supplied towards the sand through the air supply pipe 4. Air

from the fan is supplied to the pipe, and a stream of water is supplied to it at the rate of 50 -

100 mm3 per 1 m3 of air. The upper outlet of the outer casing is connected to the cyclone and

the exhaust of the workshop ventilation system.

Fig. 3.Installation of drum-type cooling. 1 - water supply system with a spray, 2 - receiving hopper, 3 - support system, 4 - frame, 5 - drive,

6 - water supply channel, 7 - water circulation system tank, 8 - water jacket, 9 - cylindrical rotatable body, 10 - spiral blade with blades, 11 -

feeder.

Thus, the sand, initially cooled in water-cooled pipes, is additionally cooled by the counter

flow of humidified air. The partially carried away volume of sand is bounced off by reflective

rings 3, and dust-like particles are deposited in the cyclone. The sand in the installation is not

only cooled, but also cleaned of unwanted dust-like particles for casting according to gasified

models. The described installation is compact and recommended for small molding areas.

Stanochniy park 25