Page 28 - february

P. 28

METALWORKING EQUIPMENT AND TOOLS

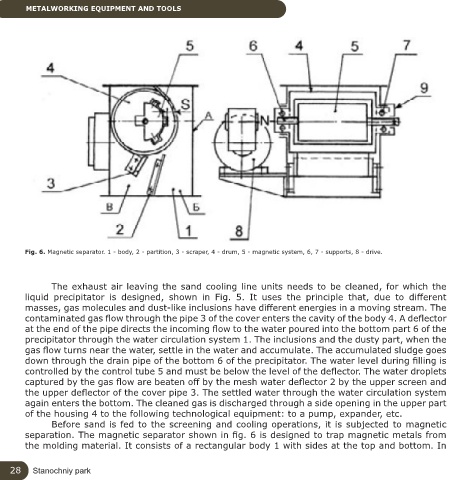

Fig. 6. Magnetic separator. 1 - body, 2 - partition, 3 - scraper, 4 - drum, 5 - magnetic system, 6, 7 - supports, 8 - drive.

The exhaust air leaving the sand cooling line units needs to be cleaned, for which the

liquid precipitator is designed, shown in Fig. 5. It uses the principle that, due to different

masses, gas molecules and dust-like inclusions have different energies in a moving stream. The

contaminated gas flow through the pipe 3 of the cover enters the cavity of the body 4. A deflector

at the end of the pipe directs the incoming flow to the water poured into the bottom part 6 of the

precipitator through the water circulation system 1. The inclusions and the dusty part, when the

gas flow turns near the water, settle in the water and accumulate. The accumulated sludge goes

down through the drain pipe of the bottom 6 of the precipitator. The water level during filling is

controlled by the control tube 5 and must be below the level of the deflector. The water droplets

captured by the gas flow are beaten off by the mesh water deflector 2 by the upper screen and

the upper deflector of the cover pipe 3. The settled water through the water circulation system

again enters the bottom. The cleaned gas is discharged through a side opening in the upper part

of the housing 4 to the following technological equipment: to a pump, expander, etc.

Before sand is fed to the screening and cooling operations, it is subjected to magnetic

separation. The magnetic separator shown in fig. 6 is designed to trap magnetic metals from

the molding material. It consists of a rectangular body 1 with sides at the top and bottom. In

28 Stanochniy park