Page 27 - february

P. 27

METALWORKING EQUIPMENT AND TOOLS

for dry sand, as well as in larger quantities is installed on the vibrodeck 3. The deck has a

if the drum unit is used for green sands. rear elastic support 4 and a front hinge 7. Below

The drum casing with a water jacket of the the apron of the deck is a funnel 6, from which

installation through the support system sifted sand is fed. All of the above elements are

3 with rollers is installed on the frame 4 attached to the bed 5. The waste is discharged

and is driven into rotation (5 - 10 rpm) by along the tray 8 to the side. There are two holes

the drive 5. By changing the diameter and on top of the casing 1. Through the hole shown

length of the water jacket 8 and the inner on the left in Fig. 4, sand is fed to the mesh

casing, as well as their inclination and speed deck cloths, and another hole (on the right) is

rotation, the cooling capacity of the molding connected to the exhaust ventilation system

sand is obtained from 2 to 6 m3/h. There for suction of dust particles, which, due to the

is a drainage system to prevent water from deck vibration and the impact of sand particles

freezing. on the funnel, rise up and go into the suction

In the sand regeneration lines, the and sedimentation system. The cleaned sand

described installations are preceded by through the opening of the funnel 6 is poured

a vibrating sieve, the developed design down into the container or into the receiving

of which is shown in Fig. 4. It consists of opening of the next installation of the through-

the following parts: body 1 made of sheet line regeneration. The vibration amplitude and

material, vibrodeck 2 with one or two mesh force are regulated by the distribution (mutual

sheets and an apron. An electric vibrator arrangement) of the vibrator unbalance weights.

A distinctive advantage of the shaker

sieve design is that, simultaneously

dusty with the removal of large inclusions

gas from the sifted sand, ventilation is

purified carried out with the removal of the

dust-like component without entering

water gas

the atmosphere of the workshop.

sludge

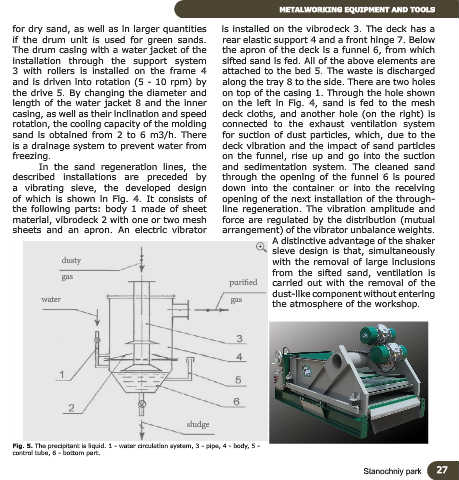

Fig. 5. The precipitant is liquid. 1 - water circulation system, 3 - pipe, 4 - body, 5 -

control tube, 6 - bottom part.

Stanochniy park 27