Page 26 - february

P. 26

METALWORKING EQUIPMENT AND TOOLS

to ventilation system

wastes

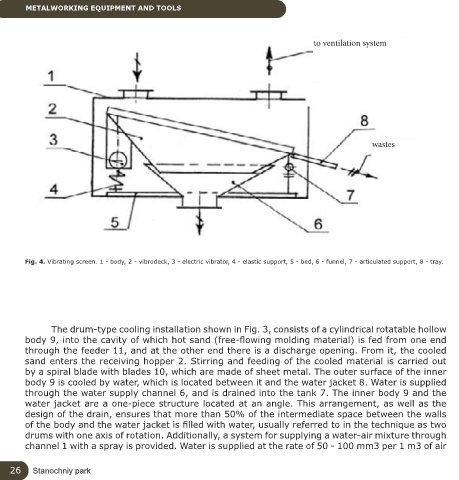

Fig. 4. Vibrating screen. 1 - body, 2 - vibrodeck, 3 - electric vibrator, 4 - elastic support, 5 - bed, 6 - funnel, 7 - articulated support, 8 - tray.

The drum-type cooling installation shown in Fig. 3, consists of a cylindrical rotatable hollow

body 9, into the cavity of which hot sand (free-flowing molding material) is fed from one end

through the feeder 11, and at the other end there is a discharge opening. From it, the cooled

sand enters the receiving hopper 2. Stirring and feeding of the cooled material is carried out

by a spiral blade with blades 10, which are made of sheet metal. The outer surface of the inner

body 9 is cooled by water, which is located between it and the water jacket 8. Water is supplied

through the water supply channel 6, and is drained into the tank 7. The inner body 9 and the

water jacket are a one-piece structure located at an angle. This arrangement, as well as the

design of the drain, ensures that more than 50% of the intermediate space between the walls

of the body and the water jacket is filled with water, usually referred to in the technique as two

drums with one axis of rotation. Additionally, a system for supplying a water-air mixture through

channel 1 with a spray is provided. Water is supplied at the rate of 50 - 100 mm3 per 1 m3 of air

26 Stanochniy park