Page 40 - APPD_Something's_Brewing_July_Aug'24

P. 40

Sustainability

In the greenhouse, there is no issue of re-wetting Cafeology

Pre-drying

via rainfall and higher temperatures are

maintained (coffee is spread along the floor so

drainage is limited – raised beds could be used

inside but these would reduce space and drying

capacity). Nevertheless, the greenhouse is an

expensive investment. The plastic sheeting that

surrounds the frame is prone to damage in high

winds and must be replaced every 5 years

anyway. Similarly, the concrete base is very

expensive and also means that the greenhouse

cannot be moved (like tarps and raised beds can)

for repurposing the ground space during the

off-season.

Pulper tower (top left) and

a worker turning coffee

hoppers above the

mechanical dryer for this final

stage of drying (any wetter

35%, and the coffee is too

sticky to unload out the

hoppers).

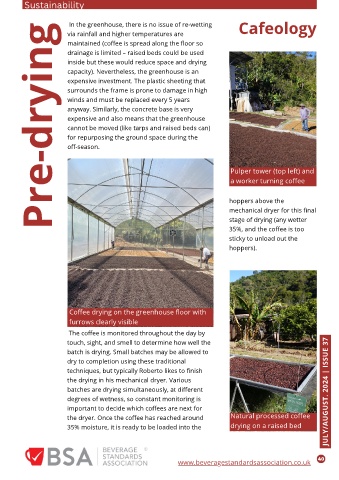

Coffee drying on the greenhouse floor with

furrows clearly visible

The coffee is monitored throughout the day by

touch, sight, and smell to determine how well the

batch is drying. Small batches may be allowed to

dry to completion using these traditional

techniques, but typically Roberto likes to finish

the drying in his mechanical dryer. Various

batches are drying simultaneously, at different JULY/AUGUST. 2024 | ISSUE 37

degrees of wetness, so constant monitoring is

important to decide which coffees are next for

the dryer. Once the coffee has reached around Natural processed coffee

35% moisture, it is ready to be loaded into the drying on a raised bed

www.beveragestandardsassociation.co.uk