Page 41 - APPD_Something's_Brewing_July_Aug'24

P. 41

Sustainability

Cafeology

Drying

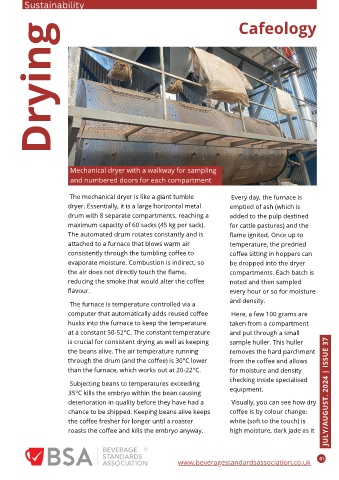

Mechanical dryer with a walkway for sampling

and numbered doors for each compartment

The mechanical dryer is like a giant tumble Every day, the furnace is

dryer. Essentially, it is a large horizontal metal emptied of ash (which is

drum with 8 separate compartments, reaching a added to the pulp destined

maximum capacity of 60 sacks (45 kg per sack). for cattle pastures) and the

The automated drum rotates constantly and is flame ignited. Once up to

attached to a furnace that blows warm air temperature, the predried

consistently through the tumbling coffee to coffee sitting in hoppers can

evaporate moisture. Combustion is indirect, so be dropped into the dryer

the air does not directly touch the flame, compartments. Each batch is

reducing the smoke that would alter the coffee noted and then sampled

flavour. every hour or so for moisture

The furnace is temperature controlled via a and density.

computer that automatically adds reused coffee Here, a few 100 grams are

husks into the furnace to keep the temperature taken from a compartment

at a constant 50-52°C. The constant temperature and put through a small

is crucial for consistent drying as well as keeping sample huller. This huller

the beans alive. The air temperature running removes the hard parchment

through the drum (and the coffee) is 30°C lower from the coffee and allows

than the furnace, which works out at 20-22°C. for moisture and density

Subjecting beans to temperatures exceeding checking inside specialised

35°C kills the embryo within the bean causing equipment. JULY/AUGUST. 2024 | ISSUE 37

deterioration in quality before they have had a Visually, you can see how dry

chance to be shipped. Keeping beans alive keeps coffee is by colour change:

the coffee fresher for longer until a roaster white (soft to the touch) is

roasts the coffee and kills the embryo anyway. high moisture, dark jade as it

www.beveragestandardsassociation.co.uk