Page 1606 - Master Catalog 2017, Inch

P. 1606

Hole Finishing

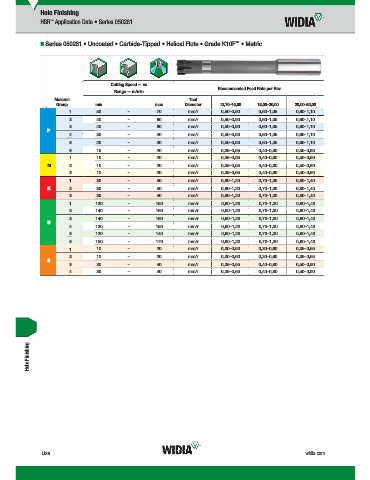

HSR Application Data • Series 050281

™

™

Series 050281 • Uncoated • Carbide-Tipped • Helical Flute • Grade K10F • Metric

Cutting Speed — vc

Recommended Feed Rate per Rev

Range — m/min

Material Tool

Group min max Diameter 12,70–15,00 15,00–20,00 20,00–32,00

1 50 – 70 mm/r 0,50–0,90 0,60–1,05 0,60–1,10

2 40 – 60 mm/r 0,50–0,90 0,60–1,05 0,60–1,10

3 40 – 60 mm/r 0,50–0,90 0,60–1,05 0,60–1,10

P

4 30 – 40 mm/r 0,50–0,90 0,60–1,05 0,60–1,10

5 20 – 30 mm/r 0,50–0,90 0,60–1,05 0,60–1,10

6 10 – 20 mm/r 0,35–0,65 0,40–0,80 0,50–0,90

1 10 – 20 mm/r 0,35–0,65 0,40–0,80 0,50–0,90

M 2 10 – 20 mm/r 0,35–0,65 0,40–0,80 0,50–0,90

3 10 – 20 mm/r 0,35–0,65 0,40–0,80 0,50–0,90

1 30 – 50 mm/r 0,60–1,20 0,70–1,30 0,80–1,40

K 2 30 – 50 mm/r 0,60–1,20 0,70–1,30 0,80–1,40

3 30 – 40 mm/r 0,60–1,20 0,70–1,30 0,80–1,40

1 130 – 150 mm/r 0,60–1,20 0,70–1,30 0,80–1,40

2 140 – 160 mm/r 0,60–1,20 0,70–1,30 0,80–1,40

3 140 – 160 mm/r 0,60–1,20 0,70–1,30 0,80–1,40

N

4 130 – 150 mm/r 0,60–1,20 0,70–1,30 0,80–1,40

5 120 – 140 mm/r 0,60–1,20 0,70–1,30 0,80–1,40

6 150 – 170 mm/r 0,60–1,20 0,70–1,30 0,80–1,40

1 10 – 20 mm/r 0,30–0,50 0,30–0,60 0,35–0,65

2 10 – 20 mm/r 0,30–0,50 0,30–0,60 0,35–0,65

S

3 30 – 40 mm/r 0,35–0,65 0,40–0,80 0,50–0,90

4 30 – 40 mm/r 0,35–0,65 0,40–0,80 0,50–0,90

Hole Finishing

U28 widia.com

H l fi i hi

U028 U029 Mi

V

i

WID M

ki

16 H l

L WID_Master16_Holemaking_Holefinishing_U028_U029_Minch_REBRAND.indd 28 h REBRANDO b 13 20154 57PM 10/29/15 1:15 PM